TECHNOLOGY

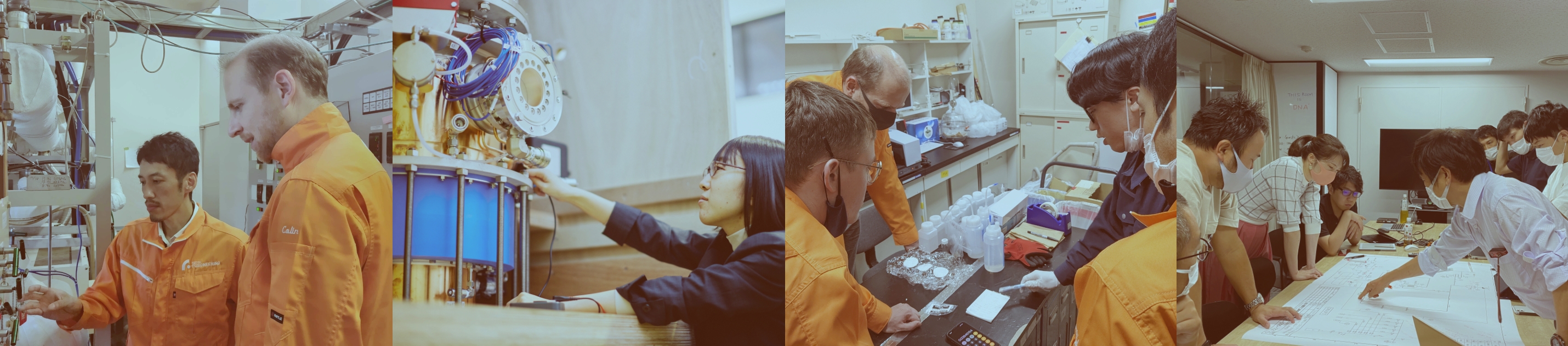

Leveraging world-class R&D facilities and specialized expertise,

we drive innovation by providing practical solutions to fast-track the path to commercial fusion.

Engineering Excellence

Our strengths

Our technical team consists of many researchers and engineers who have significant experience in fusion energy research. With a combined total of approximately 800 years of experience, the solid expertise and knowledge of our team form the foundation of our technological capabilities.

Our developments are not just technical milestones; they represent strides toward making fusion energy more practical and sustainable, aligning with KF’s commitment to pioneering solutions in the energy sector.

Illustrating Fusion Energy Power Plant and Our Enabling Technology Focus

-

Plasma Heating (Gyrotron) System

Gyrotrons provide the heating necessary to sustain a plasma in magnetic confinement-type fusion power plants.

Gyrotrons have long been the subject of research and development involving national research institutes and many engineers. Building on this technology, we are conducting R&D to improve performance and promote the global adoption of gyrotrons. Our R&D efforts include the development of higher frequencies and extended output duration ,ensuring their transition to industrial applications.

As a private company, we prioritize excellence in product management and quality assurance,

along with other aspects necessary for the successful implementation of gyrotrons.-

Gyrotrons capable of four frequency bands (104 / 137 / 170 / 236*GHz).

*236GHz is currently under development - Received orders from UKAEA and overseas start-up companies.

- Engaging in extensive cooperation with major Japanese technology and manufacturing companies for collaborative product development.

- Developing a combination of technologies that are expected to be applied not only to the fusion industry but also to other industries.

-

Gyrotrons capable of four frequency bands (104 / 137 / 170 / 236*GHz).

-

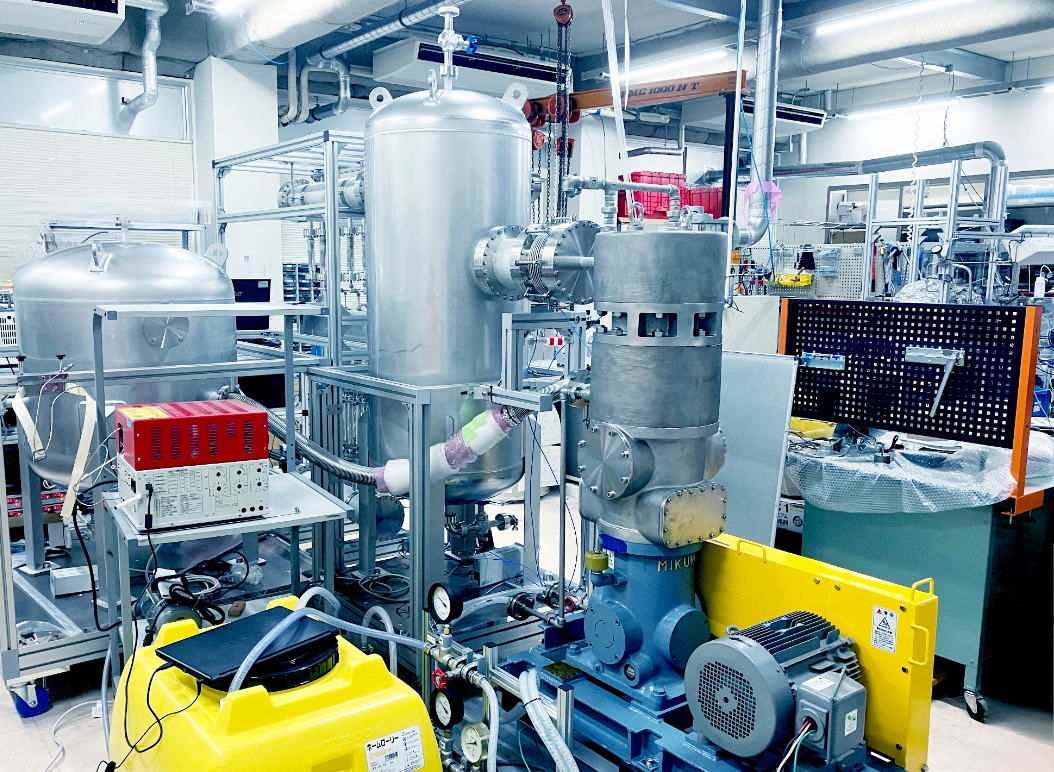

Fuel Cycle System

A key challenge in achieving stable operations of a fusion device is maintaining a continuous fuel supply. To address this, KF is advancing fuel cycle technologies, essential for circulating hydrogen isotope gases like deuterium and tritium, the primary fuels for most fusion reactions. These gases, heavier forms of hydrogen, are pivotal for achieving the high-energy output desired in fusion reactors. Our research, rooted in studies from Kyoto University and other prestigious institutions, aims to refine the processes of exhaust, separation, and circulation of these gases.

In collaboration with Canadian Nuclear Laboratories (CNL), a leader in hydrogen management, we are undertaking the UNITY-2 project. This initiative focuses on enhancing the technological maturity of fuel cycle systems. CNL’s world-renowned facilities play a crucial role in this joint effort, bringing global expertise to the forefront of our research.

- Development of technologies and equipment to enable efficient tritium extraction from liquid breeder system.

- Design and development of plasma exhaust systems (including divertors, pumps, direct internal recycling system) and separation technologies (impurity gas removal, isotope separation system, etc.) to maintain continuous burning of fusion plasma through efficient tritium recovery.

- Optimization of fuel cycle systems and investigation of cost-competitive designs.

-

Thermal Cycle System

Extracting heat efficiently from a fusion core requires innovative materials and plant designs tailored to the unique demands of fusion energy. These include managing extreme conditions like intense neutron bombardment, powerful magnetic fields, and high temperatures. At KF, we’re committed to developing a comprehensive system that not only withstands these challenges but also achieves high thermal efficiency.

Our proprietary materials and plant designs represent a leap forward in fusion technology. They are specifically engineered to handle the rigors of fusion energy production, setting new standards in durability and efficiency. This development is a crucial step towards realizing practical and sustainable fusion energy.

- Development of advanced materials (e.g., SiC composites) with high heat resistance (up to 1000°C) and low activation.

- Design and development of advanced blankets with heat recovery and tritium breeding capabilities at high temperatures, as well as the design of liquid metal molten salt loops (LiPb, Li, FLiBe).

- Design and development of advanced heat exchangers and innovative power generation cycles using helium and other media.

- Exploration of hydrogen production using zero-carbon, high-temperature heat sources derived from fusion energy, and carbon fixation technology through the pyrolysis of biomass.

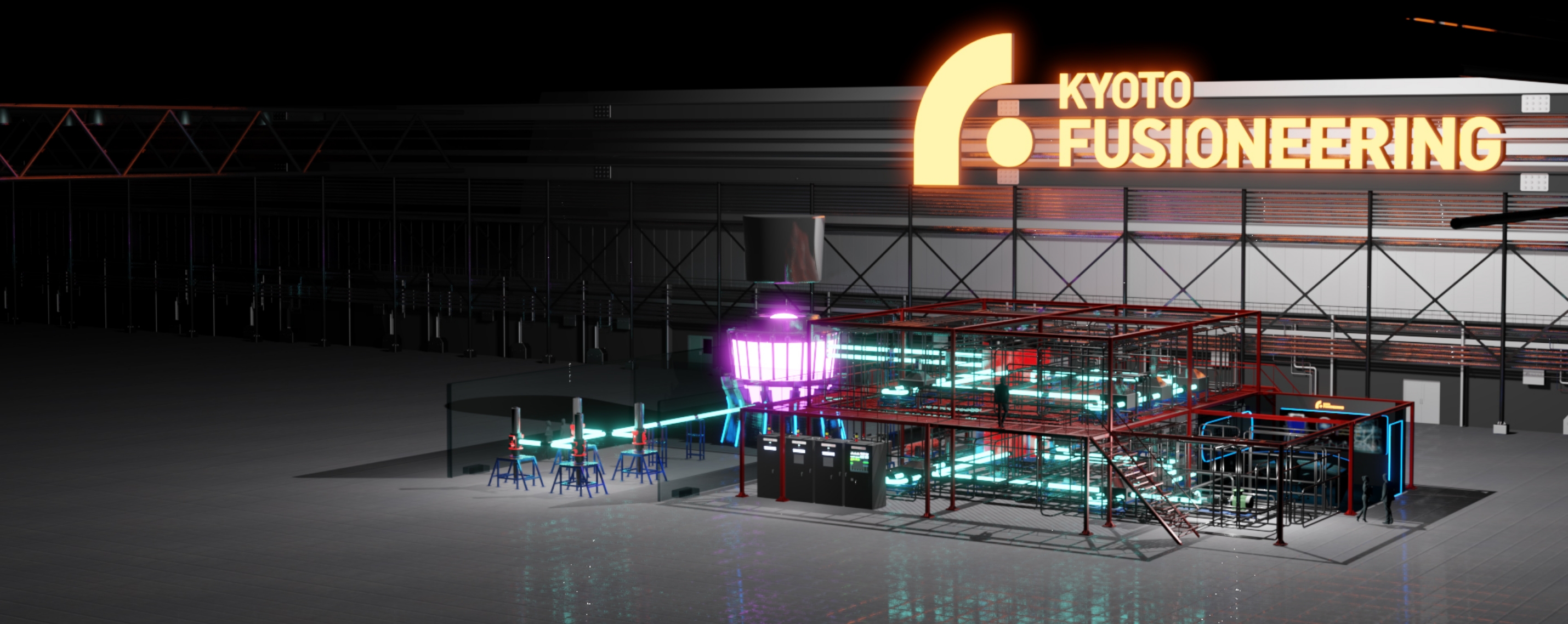

UNITY Suite

Unique Integrated Testing Facility

The UNITY Suite includes two distinct yet interconnected facilities:

-

UNITY-1: Being built at KF’s Kyoto Research Centre, UNITY-1 is dedicated to advancing the Thermal Cycle System. It simulates the high-temperature and magnetic conditions of a fusion plant to test various power generation systems. This includes innovative components such as a specialized “blanket” for efficient heat extraction, liquid metal loops, and advanced heat exchangers, all operating without radioactive materials. This facility is pivotal in harnessing and converting the immense energy generated by fusion reactions into electricity.

The UNITY-1 demonstration facility will not create a fusion reaction, and will not use any radioactive materials.

-

UNITY-2: To be situated at Chalk River Laboratories in Ontario and developed in strategic alliance with Canadian Nuclear Laboratories, UNITY-2 focuses on the complete deuterium-tritium fuel cycle. This facility is set to pioneer global standards in critical operations such as fuel exhaust, pumping, and tritium handling. UNITY-2’s test loop will play a crucial role in demonstrating safe and stable fuel supply processes for core plasma.

Technical Papers

You can see our latest research archives from the link below.

(Journal of Fusion Energy)

(Self-Cooled Yuryo Lithium-Lead Advanced)