Phase One Success Marks Major Step in Advancing High-Temperature Superconducting Magnetic Technology for Fusion Energy

Kyoto Fusioneering Ltd. (KF) and Fujikura Ltd. (Fujikura) proudly announce the successful completion of Phase One of their joint R&D project on high-temperature superconducting (HTS) magnets—critical components for next-gen fusion reactors. The project was awarded by the the UK Atomic Energy Authority’s (UKAEA), as part of its flagship STEP (Spherical Tokamak for Energy Production) programme. The programme is now led by its wholly owned subsidiary, UK Industrial Fusion Solutions Ltd (UKIFS), whose objective is to make commercial fusion energy a reality.

1. Project Goals and Collaboration Framework

The project set out to improve HTS magnet design, with a focus on understanding and minimizing AC loss—one of the key challenges in developing high-performing HTS coils for fusion applications. These insights gained from a wide range of experimental data are vital for the successful design, analysis, and manufacturing of next-gen superconducting (HTS) magnets that will be incorporated in the UKIFS’s STEP program. This project brought together fusion engineering expertise from Kyoto Fusioneering and world-class HTS wire technology from Fujikura to accelerate innovation and deliver results with real impact on fusion technology.

2. Methodology and Results

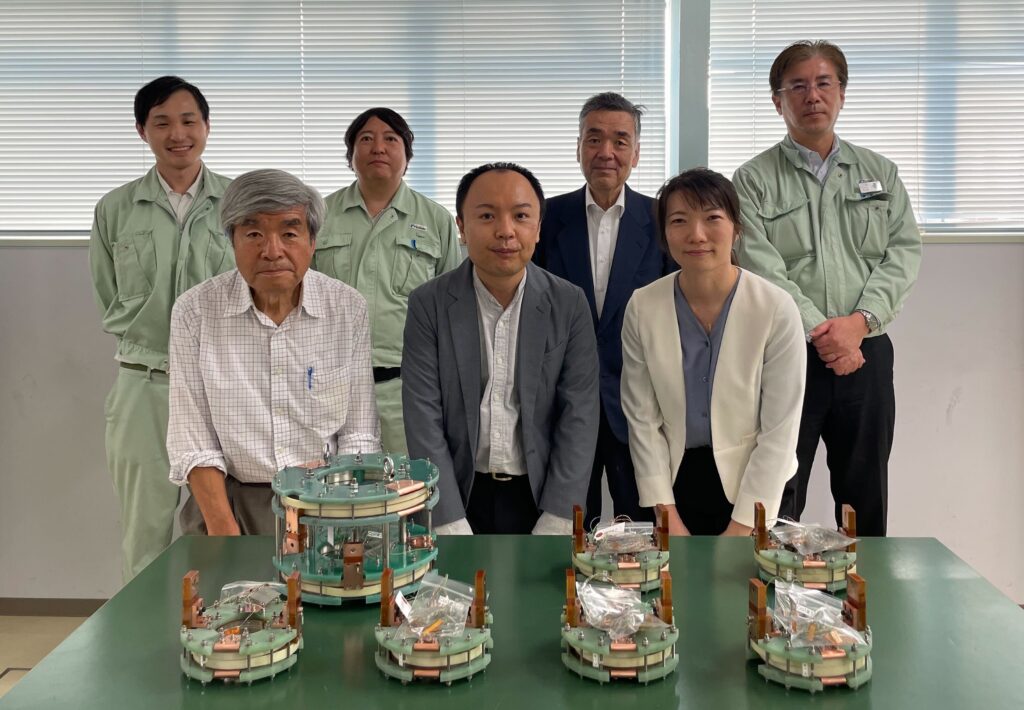

The project kicked off with the design and fabrication of prototype coils to collect critical performance data. Working closely with UKIFS, the team identified key specifications, structural parameters, and testing protocols—ensuring alignment with the physical properties and geometries relevant to HTS magnet systems. Fujikura leveraged its advanced manufacturing capabilities to produce 7 high-quality prototype coils with distinct internal structures.

In parallel, a custom-built testing environment was developed to match the specific requirements of the 7 prototype coils. Rigorous tests conducted at cryogenic temperatures revealed that the coils’ current-carrying performance, the current-voltage (I-V) characteristics of the superconductivity, closely matched KF’s simulation predictions—validating the consistency of Fujikura’s HTS wire performance.

These results confirm a critical milestone: HTS wire can be successfully fabricated into a variety of test coil structures without compromising its superconducting properties. The testing also produced reliable data on AC losses, reinforcing the strength of the overall design and the integrity of the experimental process. The project concluded with the successful delivery of core performance data to UKIFS, marking a strong finish to Phase One. The close collaboration throughout—from design to manufacturing—enabled the team to share critical insights into HTS coil fabrication.

3. Comments from Project Members

Dr. Stuart Wimbush, Principal Magnets Engineer at UKIFS

“We’re extremely pleased with the outcome of this project, and the value obtained from the contract throughout its 20-month duration. The close collaborative working approach and willingness to conduct exploratory work together with us has been a particular boon to our team, enabling extended involvement of multiple team members in the work throughout the project term. The broader exposure to the Japanese industrial sector, most prominently including HTS market leaders Fujikura alongside introductions to other potential partners, has been an added value of the contract, expertly facilitated by Kyoto Fusioneering. The quality of work delivered at every stage has been superlative.”

Dr. Sadanori Iwai and Dr. Miki Nishimura – Kyoto Fusioneering Ltd.

“We’re proud to have played a role in this groundbreaking UK initiative. This project marked KF’s first venture into the HTS magnet field, and partnering with Fujikura—renowned for their HTS wire expertise—was key to its success. We’re deeply grateful for the opportunity to collaborate so closely, combining the strengths of both teams to achieve such meaningful progress.”

Dr. Shinji Fujita and Masanori Daibo – Fujikura Ltd.

“We are honored to have partnered with Kyoto Fusioneering—an industry leader in fusion technology—and to have played a role in this advanced UK program. This project gave us valuable insights into high-temperature superconducting (HTS) magnets from a fusion energy perspective and marked a technically significant achievement for our team. We remain committed to advancing HTS technology both in Japan and on the global stage.”

4. The Growing Role of HTS Magnets in Fusion Energy

Superconducting technology is a cornerstone of fusion energy development—and its importance continues to grow. From the global progress driven by projects like ITER to the cutting-edge R&D led by both public and private sectors, superconducting magnets are central to making fusion viable.

Japan has played a leading role in this evolution. With world-class research institutes like QST at the forefront of materials science, precision engineering and magnet structure design, Japan continues to shape the future of superconducting technology in fusion.

In recent years, momentum has been building—especially among private fusion startups—toward the early practical application and the commercialization of fusion energy. A key driver of this shift is the promise of high-temperature superconducting (HTS) magnets. Building on insights from ITER and leveraging HTS’s higher critical magnetic fields, many in the field now see a path to achieving comparable plasma performance in more compact, efficient systems and on faster timelines.

HTS magnet development is emerging as one of the most pivotal technology frontiers in fusion, and Kyoto Fusioneering is proud to be part of that effort. By combining Japan’s advanced manufacturing know-how with global expertise, KF is helping shape the future of HTS technology. Through tailored design and R&D support for institutions and fusion companies worldwide, we’re committed to driving the early realization of practical fusion power.