In a nutshell:

Masataka Muraki joined Kyoto Fusioneering (KF) in April 2023, bringing with him a rich background in international business development, procurement, and new venture launches from his time at a leading construction machinery manufacturer.

Now part of our Business Development and Operations Division, he leads one of several gyrotron projects at KF, bringing gyrotron systems to global markets by bridging cultures, streamlining operations, and helping turn cutting-edge technology into real-world solutions.

You’re currently a project manager at KF. Could you tell us about your career journey so far?

I began my career in the legal department of a major construction machinery manufacturer, handling contract reviews and providing legal guidance. A few years in, I was transferred to an engine manufacturing plant and stepped into the world of procurement.

Over the next seven years, I worked as a buyer for key components used in in-house engine production. As the primary contact for US-based suppliers, I led cost-savings initiatives and gained first-hand experience in the exciting, fast-paced world of international business.

At the same time, I had the opportunity to work closely with the teams in design, production management, and quality assurance—learning the core processes and systems that drive manufacturing, right on the factory floor.

After gaining well-rounded experience in factory operations, I learned of a new internal opportunity: the launch of a joint venture focused on driving digital transformation (DX) in the construction industry and improving productivity on job sites. I applied through our internal recruitment program and made the jump.

At the time, the new company had only 13 members. Under the leadership of a manager I deeply respected, I had the chance to grow in a fast-paced startup environment—completely different from the rhythm of a large corporation. The business focused on retrofitting conventional construction machinery with IoT devices to provide ICT-enabled functionality at a fraction of the cost.

I wore many hats, taking part in everything from supply chain management and business model design to post-sales support—playing a hands-on role in launching and scaling a new business from the ground up.

Why did you decide to make the move to KF?

My secondment to the joint venture was originally meant to be temporary, with the expectation that I’d eventually return to my original company. But stepping into a completely different corporate culture opened my eyes. It sparked a desire to break out of the familiar and take on new challenges in a more dynamic, growth-driven environment.

That’s when I came across a job posting from KF. At the time, I knew almost nothing about fusion energy, but I was immediately drawn to the massive scale and potential societal impact of the field. What really stood out was that, unlike many startups chasing software solutions, KF is rooted in and committed to hardware innovation—and that struck a chord with me.

It wasn’t an easy decision—it was my first time changing jobs, and I had my share of doubts. But what won me over was KF’s solid, well-structured business model, and more than anything, the genuine excitement I felt. That sense of purpose and possibility ultimately pushed me to take the leap.

What does your role involve?

I’m the project manager for our flagship product—the gyrotron system, a cutting-edge plasma heating device we supply to Tokamak Energy, a global leader in fusion energy based in the UK.

I oversee the entire project, from coordinating tasks and resolving issues to managing progress, handling contract negotiations, and serving as the main point of contact with the customer.

One thing I always keep in mind when managing a project is what the customer truly wants. In international business, differences in commercial practices and standards can lead to mismatched expectations. That’s why I prioritize open, consistent communication with our partners so we can keep things moving forward without detours.

That said, we can’t always meet every single request. So, I find myself playing the role of mediator—striking the right balance between what our engineers and suppliers can deliver, and what the customer needs. KF is a deeply technology-driven company, and we want to let our engineers focus on what they do best. So, on the business side, we try to handle the operational complexity, freeing up our technical teams to innovate in the best environment possible.

What challenges have you faced, and what makes the work rewarding?

Back at my previous company, everything was handled by specialized departments, like design reviews and technical documentation. But at KF, with our lean team structure, the business division often has to step in and take ownership of those areas too. That shift was a real challenge at first, especially since I didn’t have much product knowledge when I joined.

There were also plenty of moments where we needed to take a unique, tailored approach, like figuring out complex export procedures and adapting to project-specific needs that didn’t have a clear precedent. It was definitely a steep learning curve.

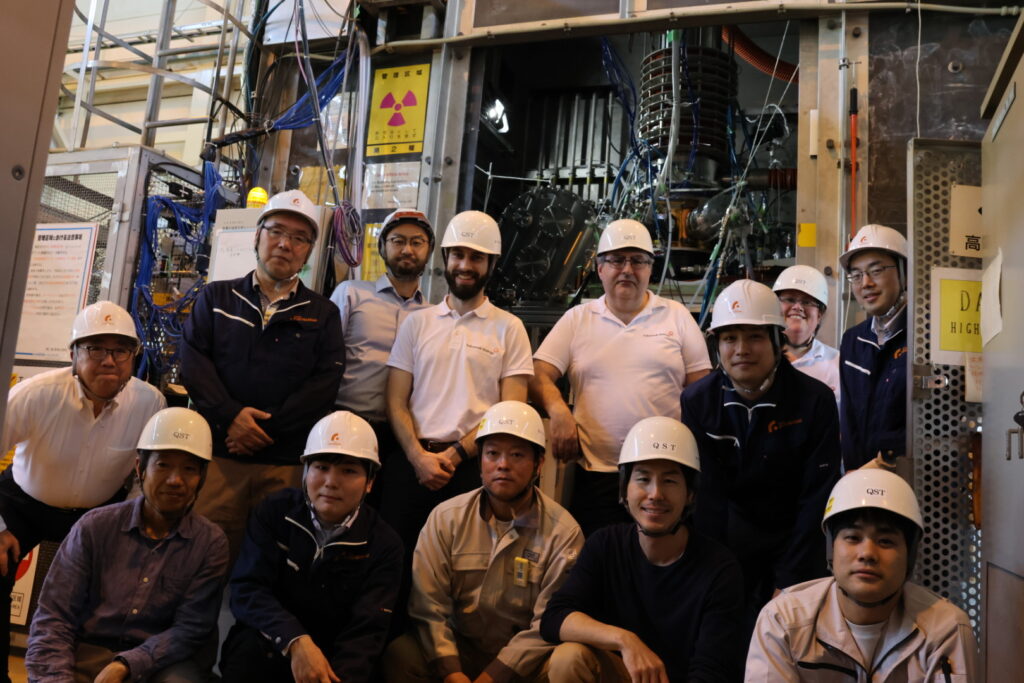

But those challenges are also what make the work so fulfilling. I get to collaborate with a diverse, cross-generational team of professionals, each bringing a unique perspective and set of skills. That kind of environment keeps me growing. One of the most rewarding moments so far came in February, when I visited Tokamak Energy’s facility and saw our equipment being installed on-site. Witnessing the project take shape in real time—and hearing heartfelt appreciation from their team—was a powerful reminder of why we do what we do.

How has your past experience shaped your work at KF?

Managing a project is more than timelines and tasks—it comes with a mountain of documentation: drawings, specifications, contracts, and more. My background at a large manufacturing company gave me the ability to envision the ideal end state and guide the team there step-by-step. At the joint venture, I learned something equally important: how to build something from scratch. That hands-on startup experience taught me to stay resilient and adaptable—skills that have proven invaluable in KF’s fast-moving environment.

Above all, I’ve learned that the key to successful project management is building trust—getting close to your counterparts, really understanding their concerns, and earning their confidence. It may sound like a cliché, but no matter the product or industry, trust moves things forward. Early on, things didn’t always go smoothly. But once I built a strong relationship with the client—where they would say, “If it’s for Muraki-san, we’ll make it work”—that’s when the project started gaining real momentum.

Lastly, what goals are you aiming to achieve going forward?

Right now, my top priority is to successfully deliver the Tokamak Energy project on time and on target. By delivering results, we can further strengthen the credibility and competitiveness of our gyrotron system, opening doors to future opportunities. Beyond that, I hope to apply the project management know-how we’ve gained and apply it to upcoming initiatives, building a stronger foundation for KF’s global expansion.

Fusion energy is one of the fields where Japan has a true technological advantage and the potential to lead globally. I’ve seen a real surge in interest recently around fusion energy in conversations with people from all walks of life. It’s clear that expectations are rising.

By getting more Japanese companies involved and pushing forward the industrialization of fusion, I hope to help amplify Japan’s presence on the global stage—not just as a participant, but as a leader in the next era of energy.