In a nutshell:

Since joining Kyoto Fusioneering (KF) in February 2024, Tim has played an active role in advancing R&D on the fusion fuel cycle. His responsibilities include the development of the fuel cycle simulator FFCSim and project lead of SyrVBreTT (Synergy Consortium – Fuel Cycle Tritium Technologies) Project. With a Ph.D. in engineering from the Karlsruhe Institute of Technology (KIT), one of the world’s leading institutions in fusion research, he is now part of Kyoto Fusioneering Europe (KFEU), working in close collaboration with international colleagues around the globe.

When did you first become interested in fusion energy?

I studied chemical and process engineering from my bachelor’s through to my master’s degree at the Karlsruhe Institute of Technology (KIT), and one of the courses I took introduced me to fusion energy. That was the moment I became truly fascinated by it. While I had heard of fusion before, learning about its principles, which are so different from other energy sources, sparked a much deeper interest.

From then on, I took every fusion-related course available during my studies. In one of them, Dr. Chris Day, now our Senior Vice President and EU Director, gave a lecture on vacuum engineering at KIT. He explained how his research group was contributing to fusion and highlighted the vital role of vacuum systems in fusion technology.

Meeting him and attending his class left a strong impression on me, and I decided to apply for a Ph.D. in his group. I was thrilled to begin my research in fusion under his supervision.

What kind of research did you do as a Ph.D. student?

I was part of a research group contributing to EUROfusion, the European fusion program. My research focused on the divertor vacuum pumping system for Europe’s demonstration fusion power plant projects, as well as on the direct internal recycling system for the fusion fuel.

More specifically, I investigated the use of mercury-driven diffusion pumps—high-vacuum pumps compatible with tritium. These pumps are seen as a promising alternative to cryopumps, as they can operate continuously with a much lower tritium inventory. I found the interface between numerical and experimental work incredibly rewarding. I had long wanted to be involved in fusion research and realizing that our efforts were pushing into new and innovative territory was very exciting.

Naturally, there were challenges. As with most experiments, we had to adapt the experimental pump setup in the mercury lab and understand the key involved physics to model the pump in the simulations. But I found that these moments are the ones that contribute to the learning and growth process the most.

After your Ph.D., what led you to join KF, especially with other fusion startups out there?

The turning point was meeting some KF members at an international conference. KF already had a strong presence at these events, so I was familiar with the company. What really convinced me, though, was hearing about KF’s core philosophy: providing the essential infrastructure and systems for fusion devices.

That vision stood out to me. Unlike other startups focused solely on building their own reactors, KF was committed to enabling the entire fusion ecosystem. I found it inspiring that KF’s success is tied to the success of fusion startups around the world. If the ecosystem thrives, KF thrives too.

At the same time, KF was in the process of establishing its European office, which felt like the perfect opportunity for me to join and contribute.

Would you tell us about your current role at Kyoto Fusioneering (KF)?

As a Project Fusion Engineer in the Fuel Cycle Department, my primary focus is on UNITY-2. For example, together with my colleague Jonas in Germany—who joined KF at the same time as I did—we have been developing FFCSim, a process simulator for the fusion fuel cycle. FFCSim will integrate tightly with the system performance data gathered at UNITY-2. It allows us to optimize the tightly integrated dynamic fuel cycle systems and tailor the fuel cycle to different applications and throughputs.

I also lead SyrVBreTT (Synergy Consortium – Fuel Cycle Tritium Technologies) Project, one of two German government grant–funded initiatives. In this project, we are developing demonstrator units for fuel cycle equipment like metal foil pumps and a pellet reaction system, in collaboration with KIT and the University of Stuttgart.

In this role, I often draw on the experience I gained during my Ph.D. experience at KIT. At the same time, I continue to learn, which is essential for designing new components. Although challenging, collaborating with colleagues to advance our R&D and seeing our projects progress gives me a strong sense of fulfillment.

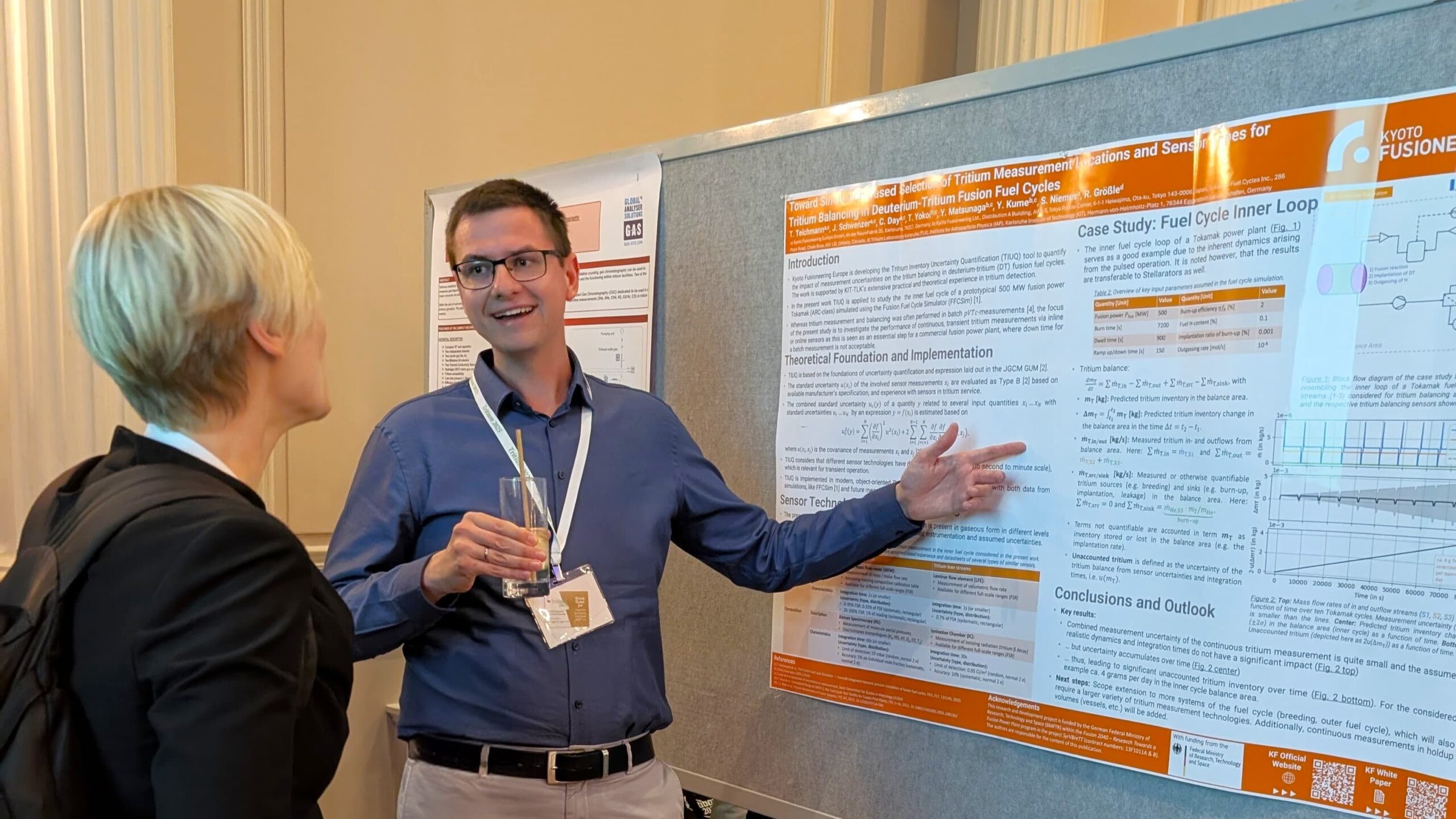

I also take pride in knowing that my contributions to projects like FFCSim and SyrVBreTT help strengthen KFEU’s leadership position in fusion fuel cycle technology. Additionally, I enjoy sharing and discussing KF’s work at international conferences and speaking with potential collaborators and customers. For example, I recently presented our work at the 14th International Conference on Tritium Science and Technology, held from 21-26 September in Ottawa, Canada, where leading tritium researchers and fusion developers from around the world participated.

Beyond R&D, I also handle various organizational tasks, from engaging with European vendors to procuring subcomponents. This helps us build a robust European supply chain and strengthens our presence in Europe.

Since joining KF as a process engineer, what kinds of challenges have you faced?

One of the biggest challenges has been juggling multiple responsibilities. In addition to my work on the fusion fuel cycle system, I have also taken on administrative tasks as our EU team continues to grow. Together with Natsuko Fukuda, who played a key role in setting up our office, we’ve managed a significant amount of paperwork. (Check out our blog about KFEU’s establishment!)

Another challenge has been learning how to communicate professionally with vendors, since I had just completed my Ph.D. when I joined KF. Negotiating costs and delivery timelines is part of the job, and I’m steadily improving my communication skills in this area.

Although there has been a lot to learn, the support from my team members and the ability to build on my Ph.D. experience have helped me overcome these challenges and continue growing in my role.

As a team, you’re working on fusion. What’s the atmosphere like in the KFEU team?

When we first started, there were only three of us. As new members have joined, the team has become much more dynamic. At KFEU, we each bring our own expertise but work closely as a team. Since we all share the same floor, it’s easy to ask questions, exchange ideas, and quickly get input from others when facing a challenge, which I think is essential for effective collaboration.

We also regularly have lunch together, where conversations go beyond work to our personal lives. And when colleagues from other countries visit, we make sure to welcome them and share meals together. That sense of camaraderie really strengthens our teamwork and makes our workplace even more enjoyable.

Lastly, what goal would you like to achieve at Kyoto Fusioneering?

In terms of my personal career, I hope to one day lead an R&D team. What I truly enjoy is working on our company vision collaboratively—bringing together and enabling different perspectives and skill sets to tackle major challenges, especially those connected to building the first fusion power plant. Ultimately, my goal is to successfully deliver the projects I’m involved in and, through collaboration with other companies, contribute to building the world’s first fusion power plant as part of a sustainable clean energy ecosystem.