At the heart of a fusion power plant lies a complex interplay of various components, each crucial for its functioning. Our last episode shed light into the Fuel Cycle, which manages the processing of fuel materials within the reactor to sustain fusion reactions efficiently. In this episode, we will focus on another integral component: the breeding blanket, which plays a crucial role in capturing and utilising the energy generated by fusion reactions, while also enabling the production of tritium needed to fuel the reactor. The breeding blanket is one of the most important, complex, and novel technical systems of future fusion reactors and any deuterium–tritium fusion power plant that build on ITER’s accomplishments. We will discuss also how Kyoto Fusioneering (KF) is developing this key enabling technology.

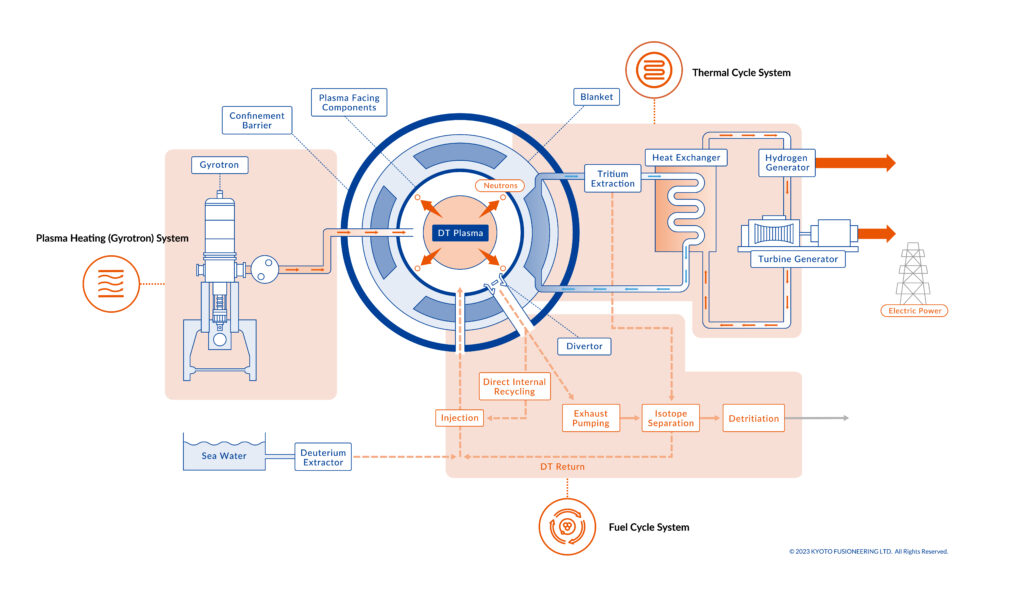

To comprehend the significance of the breeding blanket, it is important to understand the basics of energy production through magnetic confinement fusion. Despite several ways exist to create a plasma, such as for instance inertial confinement, in magnetic confinement, the fusion a plasma is confined in a vacuum chamber by strong magnetic fields. Fusion reactions take place in this plasma, releasing a huge amount of energy, in the form of neutrons and helium nuclei.

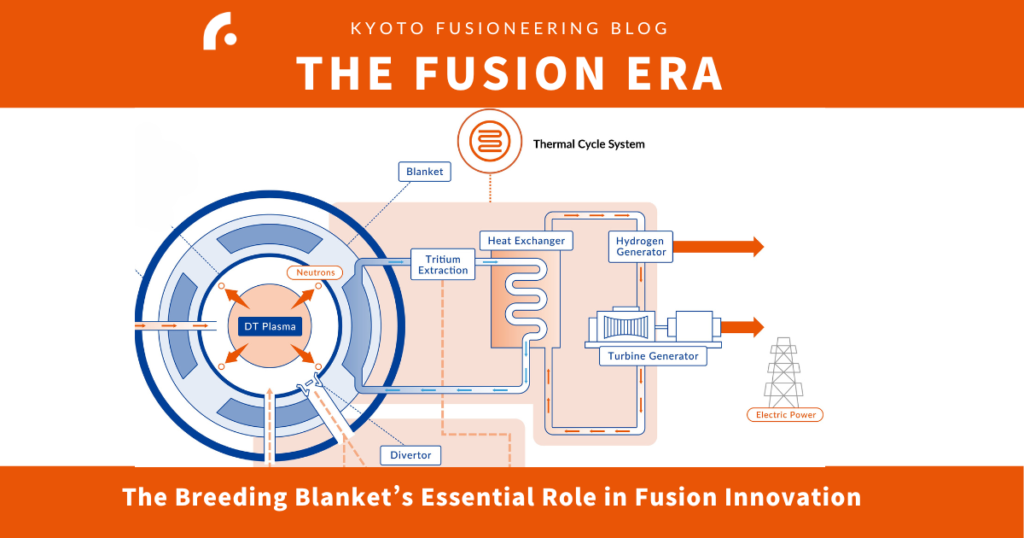

The breeding blanket, located near the plasma confinement area, serves as the primary interface between the fusion core and the rest of the power plant. Positioned adjacent to the plasma, it intercepts the energetic neutrons emitted during fusion reactions, ensuring efficient capture for energy production and tritium breeding, the letter being fundamental to guarantee the fuel self-sufficiency.

The breeding blanket perform several functions, essential to the functioning of the fusion reactor:

- Firstly, it must absorb the energy transported by neutrons (4/5 of the total energy produced by deuterium-tritium reactions). The other 1/5 of the total fusion energy, associated to helium nuclei (or alpha particles), plus the ancillary heating power, is deposited onto the so-called Plasma Facing Components (PFCs), i.e. the first wall (integrated into the front part of the blanket), limiters and divertors. Conversion of this energy at relevant thermodynamic efficiencies requires coolants at adequate conditions of temperature and pressure. This has a strong influence on the reactor engineering.

- Secondly, it must produce enough tritium by capturing fusion neutrons in lithium-containing materials (in solid or liquid form). A 2000 MW fusion power plant is expected to consume about 112 kg of tritium per full power year, despite 30-40 kg of estimated worldwide tritium availability. This makes it clear that the breeding blanket must produce and extract the bred tritium to achieve tritium self-sufficiency (i.e. it must produce its own fuel).

- In addition, the breeding blanket must be designed to enable efficient extraction of tritium and minimise losses of tritium.

- Finally, the blanket, together with the vacuum vessel, must effectively protect various components from nuclear radiation (e.g. superconducting magnets and other devices outside the reactor). The blanket is named after this blanketing function.

Beyond energy production and tritium breeding, the breeding blanket also acts as a protective shield, mitigating the harmful effects of neutron radiation on surrounding components. By absorbing and dispersing neutron energy, it helps maintain the integrity and longevity of the reactor systems, particularly those utilizing advanced materials like low-temperature or high-temperature superconductors.

Other requirements of the breeding blanket are not discussed here in depth but come from the need to have a low influx of impurities from the plasma facing surface to the plasma, components called limiters to cope with transient scenarios such as startup and shutdown, and interfacing systems management.

The complexity of the breeding blanket functions necessitates dedicated external cycles for processing (a gas or liquid is cycled many times over the course of day and can be cooled or processed), known as the Fuel Cycle and Thermal Cycle. These loops are integral to managing and optimizing the reactor’s performance, ensuring efficient energy production and tritium breeding. Kyoto Fusioneering specialises in these plant enabling technologies, through design and development of the facilities UNITY-1 (focused on thermal cycle and power conversion cycle) and UNITY-2 (focused on fuel cycle).

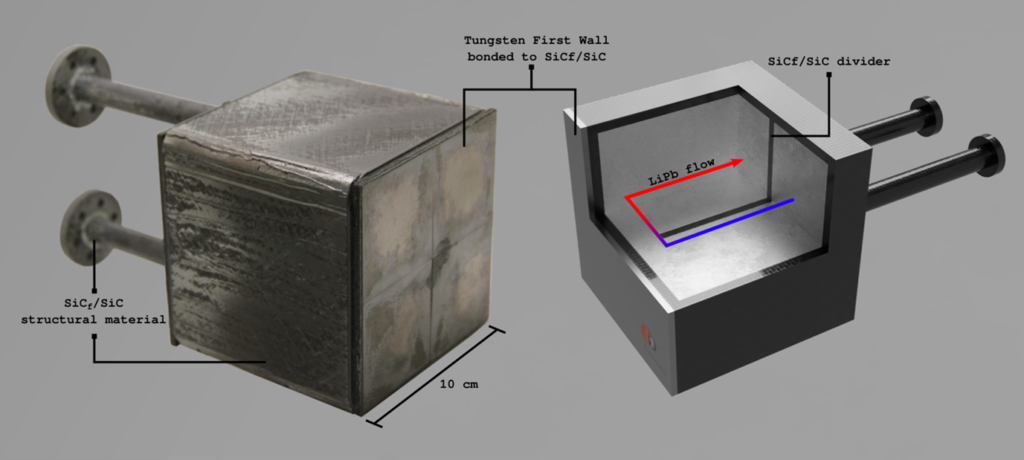

– Kyoto Fusioneering’s SCYLLA© (Self-Cooled Yuryo Lithium-Lead Advanced) Blanket for Commercial Fusion Reactors

SCYLLA© represents KF’s commercial iteration of the established self-cooled-lithium-lead (SCLL) design. This design includes a self-cooled lithium-lead blanket utilizing lithium-lead as both tritium breeder and coolant, alongside SiCf/SiC as structural material. Additionally, it incorporates a plasma-facing first wall made of tungsten or tungsten alloy for protection against sputtering and plasma disruptions. Collaborating with Kyoto University, KF is developing fusion-grade interface-less SiCf/SiC material, exhibiting stability under low displacement-per-atom (dpa) irradiation. Kyoto Fusioneering collaborates with United Kingdom Atomic Energy Authority (UKAEA) to irradiate samples and to perform post-irradiation experiments, with the aim of improving the characteristics of the material. A collaboration agreement between UKAEA and Kyoto Fusioneering was signed early 2023 to advance materials development for commercial fusion energy.

The proposed SCYLLA© blanket design would permit to achieve hot temperatures of the coolant/breeder at the outlet of the blanket, distinguishing it from traditional concepts and opening new avenues for hydrogen production, decarbonization and high-efficiency electricity production.

Authors:

Luigi Candido

Jack Taylor

Vojna Ngjeqari