In last month’s Fusion 101 Series, we explored the role of liquid metals in our cutting-edge integrated test facility, UNITY-1, and briefly introduced one of its unique components—the Vacuum Sieve Tray, or VST. This device plays a crucial role in extracting tritium, a key fuel for fusion energy, from liquid lithium-lead (LiPb) under simulated fusion conditions.

If you missed that post, you can catch up [here].

In this ninth edition of Fusion 101, we’re taking you inside the VST—explaining how it works, why it matters, and the role it could play in making fusion energy a reality.

Note: For testing at UNITY-1, hydrogen is used instead of tritium.

How the Vacuum Sieve Tray Works

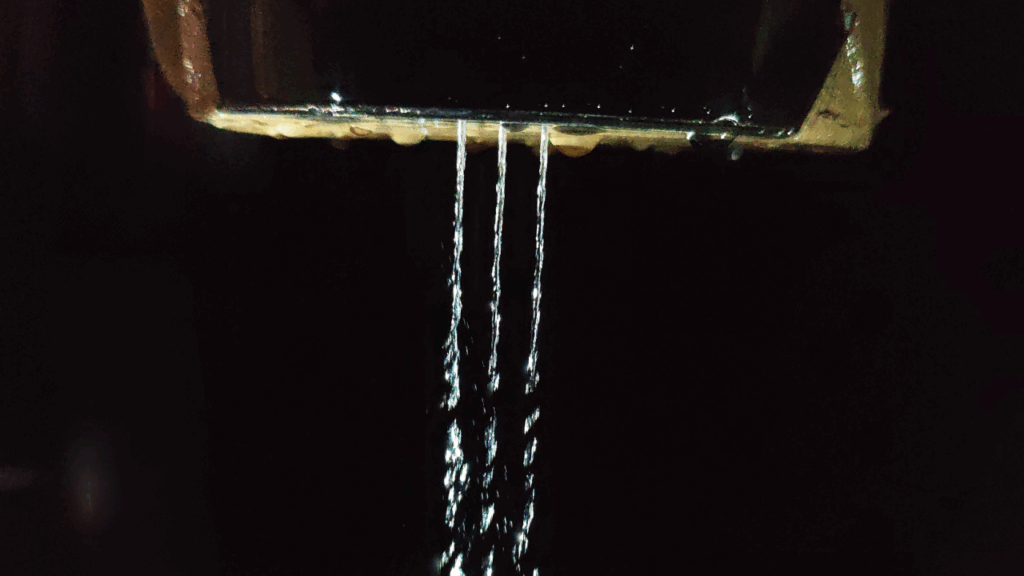

Let’s start with a quick look at this video:

What you’re watching is liquid lithium-lead heated to over 400°C, cascading through the VST in the form of tiny droplets.

The VST is built to recover tritium—a key fuel for fusion—produced when high-energy neutrons from fusion reactions interact with lithium in the blanket, a structure that surrounds the fusion core. True to its name, the Vacuum Sieve Tray operates under vacuum conditions, using a tray system that lets lithium-lead drip through like a sieve, making tritium extraction possible.

As the video shows, the VST disperses the tritium-containing liquid metal into small droplets. When the surrounding gas pressure is reduced, tritium is released from the droplets and collected as a gas—ready for further processing. It’s the same principle as soda fizzing when you crack it open—lower the pressure, and the hidden gas bubbles out.

Since a single pass isn’t enough to extract all the tritium, the VST is equipped with multiple trays, allowing the process to be repeated for greater efficiency.

Our Efforts in Tritium Recovery

At Kyoto Fusioneering, we’re working at the forefront of hydrogen isotope recovery technology—developing and testing our Vacuum Sieve Tray (VST) to help unlock the future of energy. We began with small-scale experiments using water instead of molten metal to study and fine-tune two critical factors—droplet size and flow rate—both essential for maximizing tritium extraction from lithium-lead.

Building on these results, we manufactured the VST and installed it in UNITY-1. Here, we’re running integrated testing that replicates real-world operating conditions. The setup includes heaters to keep the lithium-lead at the right temperature, sensors to detect hydrogen levels, flow meters, and circulation piping—all working in sync to test the full system under real operating conditions.

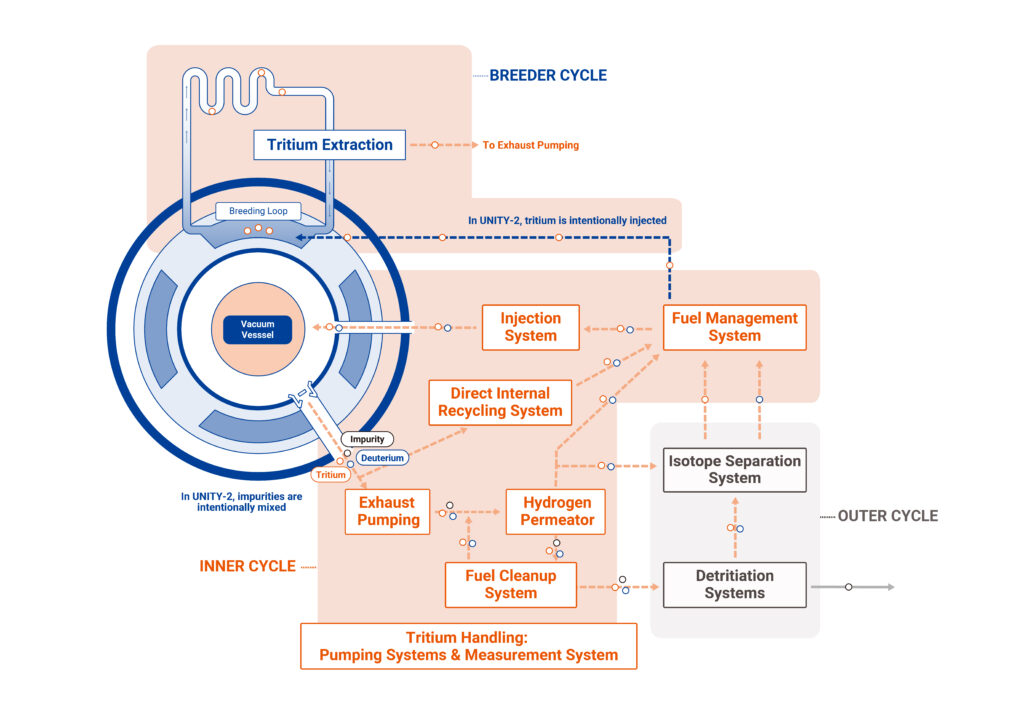

Once we’ve collected enough performance data, the next step will be full tritium trials. These will take place not at UNITY-1, but at UNITY-2—a new facility under development in Canada by Fusion Fuel Cycles Inc, our joint venture with Canadian Nuclear Laboratories (CNL).

UNITY-2 is designed to demonstrate a complete fusion fuel cycle system, continuously supplying tritium and deuterium to a reactor core. In this setup, the VST will extract tritium from lithium-lead and safely deliver it to the core via dedicated storage and pumping systems—distinct from those in UNITY-1.

Developing a stable, sustainable supply of tritium is essential to making fusion power a reality—and that’s exactly what we’re working toward. We’ll keep sharing our progress on the VST and other innovations right here on the blog, so stay tuned!

*If you’d like to learn more about the VST in detail, check out this poster.

Subscribe to Our Newsletter (LinkedIn)

Follow Us on X, LinkedIn