We’re excited to share that a new experimental device that we developed has arrived at our R&D facility in Tokyo!

This device is designed to a valuable piece for experiments: testing the core functions of the fusion fuel cycle system—a critical technology that ensures a steady supply of tritium and deuterium, the fuels that power fusion reactions. It will eventually be integrated into our next-generation UNITY-2 facility in Canada.

In this blog, we sit down with Dr. Suneui Lee, who leads the R&D on this project, to explore the system’s unique features and how it’s paving the way for the future of fusion fuel storage, which is the heart of the fuel management system

Can you tell us more about this device?

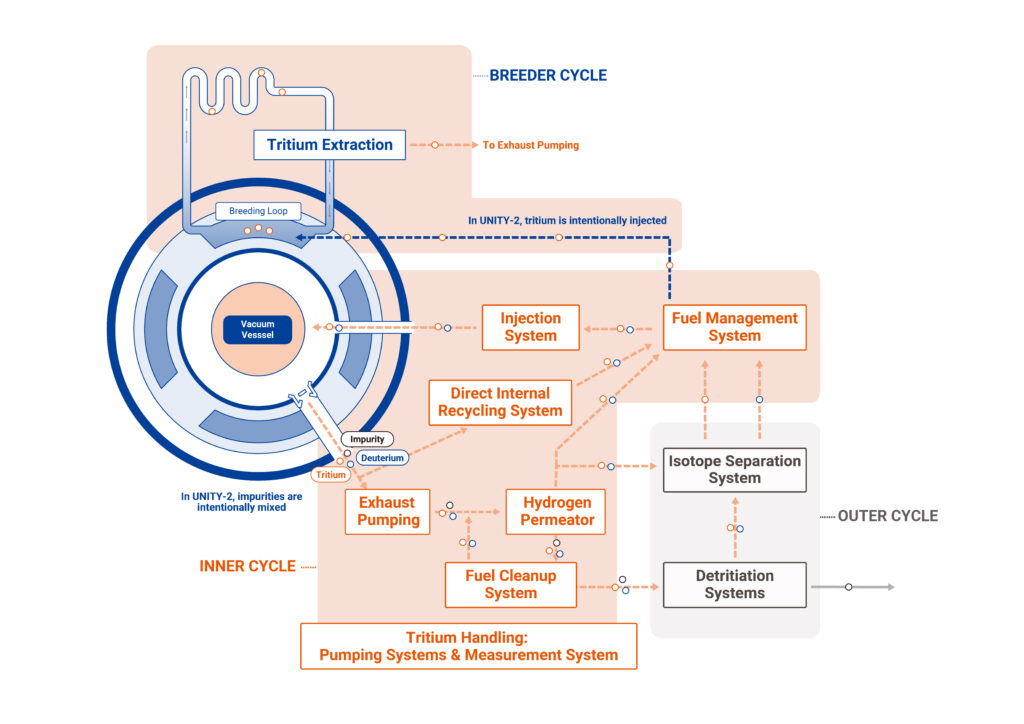

This new experimental system is designed to test technologies for the safe and efficient storage and retrieval of tritium and deuterium, which are the hydrogen isotopes used as fuel in fusion reactors. (See the diagram above labeled “Fuel Management System.”)

At room temperature, tritium and deuterium exist as gases, making them difficult to store in large quantities. Storing them in their gaseous form would require massive spherical tanks—like those used for city gas—and could pose a safety risk in case of an unintended tritium gas leak.

To solve the storage challenge, we’ve developed a system that uses a hydrogen-absorbing alloy called ZrCo (zirconium-cobalt). This material can safely absorb and release hydrogen isotopes under controlled temperature and pressure conditions. At room temperature and atmospheric pressure, ZrCo remains stable—with virtually no absorption or release—making it ideal for long-term storage. ZrCo can absorb high hydrogen amounts, by factors more than according to the weight of the storage material, enabling much more compact storage than by using conventional low pressure gas tanks.

This new device is designed to help us determine the optimal storage conditions for using ZrCo in future fusion power plants. It will also test how the material performs over repeated use.

Note: These tests will be conducted using hydrogen and deuterium—not radioactive tritium—to ensure a safe testing environment. The found solution will finally be validated in our UNITY-2 test facility.

How is this different from the previous device featured in one of our earlier Fusion 101 blogs?

(Read the previous Fusion 101 blog here)

The new system has been specifically designed to meet the requirements for integration into UNITY-2. Unlike earlier setups, this version is part of a coordinated system that includes impurity removal from hydrogen isotopes and simulated fuel injection into the plasma containment vessel—the core of the fusion reactor.

To boost performance and efficiency, we’ve made several key upgrades:

- Equipped two tanks to control hydrogen isotopes.

- Optimized the layout of pumps and components for better flow

- Adjusted pipe diameters to reach better vacuum levels

These design enhancements are the result of close collaboration and hands-on problem-solving with our engineering team—bringing us one step closer to a fully operational fuel cycle system for future fusion power plants.

What was your impression when you saw the completed device?

I had seen the system many times in 3D modeling, but seeing it in person was a completely different experience—it was much larger than I had imagined!

We’re now preparing test procedures that simulate operations at UNITY-2. I’m really excited to begin testing and data collection, and in turn contribute to the development of UNITY-2.

What are you currently working on with the new system?

Right now, we’re focused on verifying the device’s initial performance. This includes creating vacuum conditions, applying heat, and tracking key data, including how long it takes to evacuate hydrogen.

This baseline testing is crucial because it helps us determine whether any unexpected results in future tests are due to the system’s original condition or changes that occur during operation.

I’m working closely with Dr. Naoko Ashikawa, a leading expert in fusion energy, and Daiki Kikuchi, my mentor, as we carefully evaluate:

- How to approach improvements when we encounter unexpected results

- What data we need to collect at this stage

- Whether differences between test results fall within acceptable limits

What tests are planned for the future?

One of our upcoming tests will examine how ZrCo recovers its performance after repeated use. It’s known that vacuum pressure levels significantly impact the material’s regeneration process. Since the new device can achieve lower vacuum pressure levels than the previous system, we expect that we’ll be able to compare regeneration efficiency under different vacuum conditions.

We’re also planning tests to observe how ZrCo changes over time. When hydrogen gas is introduced into the ZrCo ingot, and then heat treated, it becomes powdery (see photo below).

In general, this powdered form is more difficult to handle than compared to its initial chunk state. Before implementing this system in UNITY-2, we plan to use this device to establish a method for safely handling powdered ZrCo.

As I shared in a previous interview, seeing our design come to life and move into the testing phase has been incredibly rewarding. Every new challenge is a chance to grow, and I’m learning so much every day. (Read Dr. Suneui Lee’s full interview here)

This project has been an invaluable experience. I’m very motivated by the opportunity to contribute to UNITY-2 and the future of fusion energy—and I’ll continue embracing new challenges as I grow as an engineer.

Thank you, Suneui!

We’re excited to follow the progress of the fuel storage system tests.

These tests mark a critical step toward building a reliable and efficient fusion fuel cycle system.

We’ll continue to share updates on our latest technological developments through our blog and social media channels, so stay tuned!

Subscribe to Our Newsletter (LinkedIn)

Follow Us on X, LinkedIn, Facebook