At Kyoto Fusioneering, we’re pioneering the development of a groundbreaking technology—the Fusion Thermal Cycle System—a cutting-edge technology that captures the intense heat from fusion reactions and transforms it into usable electricity.

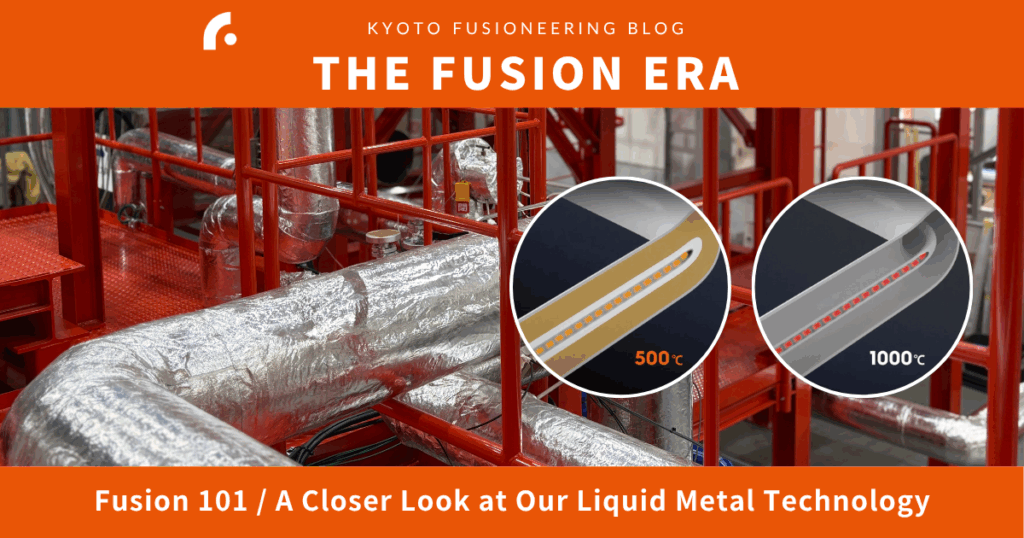

To demonstrate this technology, we’re building UNITY-1: an integrated experimental plant housed at our Kyoto Research Centre. Designed to replicate the extreme conditions of a fusion power plant, UNITY-1 serves as a proving ground for power generation technologies operating under fusion-relevant conditions.

So how do you move heat that exceeds 1000°C and then convert it into electricity at a much lower temperature of around 500°C?

The secret lies in liquid metal.

At UNITY-1, we use liquid metal to extract and transport heat. This high-temperature liquid flows through specialized piping to deliver thermal energy where it’s needed most: for power generation and hydrogen production. In this installment of our Fusion 101 blog series, we’re taking a closer look at one of the core elements of the Fusion Thermal Cycle System: liquid metal.

Why Use Liquid Metal?

In thermal and nuclear power generation, heat energy is produced either by burning fossil fuels or through nuclear fission. This heat is then used to boil water, generating steam that drives turbines to produce electricity. These systems typically operate at temperatures around 600°C for thermal and 300°C for nuclear.

Fusion energy, however, pushes the limits even further—producing temperatures well beyond those of conventional systems. To harness this extreme heat safely and efficiently, we turn to liquid metal instead of water. While water-based systems are technically feasible, extracting such high temperatures with water creates immense pressure.

Liquid metal changes the game. It can carry extreme heat while operating under much lower pressure, making it both safer and more efficient for fusion power applications. At UNITY-1, the heat carried by liquid metal is transferred to compressed air through a heat exchanger. This superheated air then drives a turbine, generating clean electricity.

What Kind of Liquid Metal?

Among the various candidates, UNITY-1 uses a specially selected lithium-lead alloy (LiPb) as its liquid metal.

Why LiPb? It combines exceptional thermal conductivity with chemical stability, two crucial traits for safely transporting heat in extreme environments. Pure lithium, though attractive for fusion, reacts easily with oxygen and water, making it difficult to manage. By alloying it with lead, we avoid those risks while retaining its useful properties.

Even when cooled to around 500°C, LiPb remains in liquid form. This allows efficient heat transfer without putting excess strain on pipes or surrounding components.

LiPb is more than just a heat carrier; it also plays a critical role as a fuel generator.

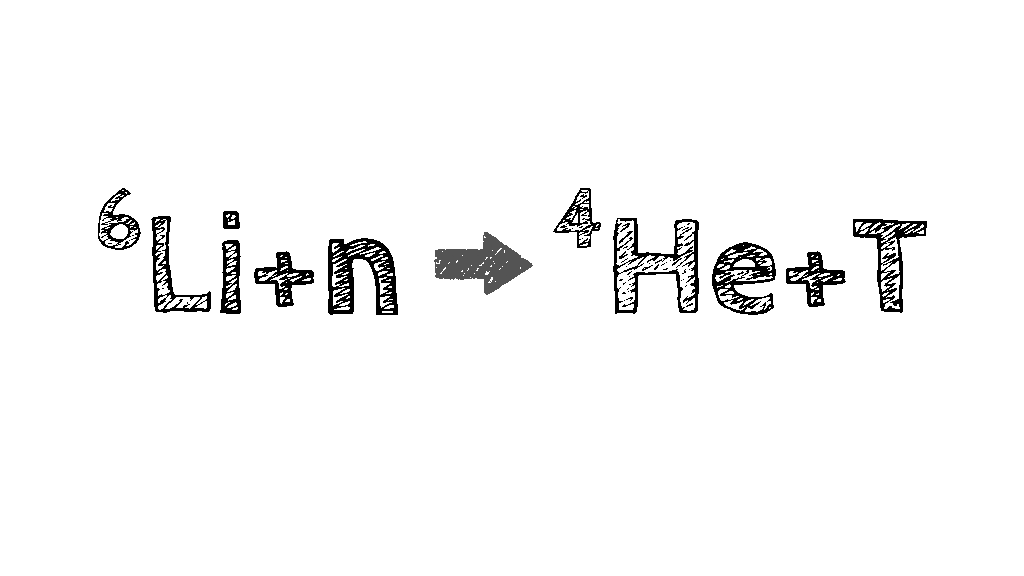

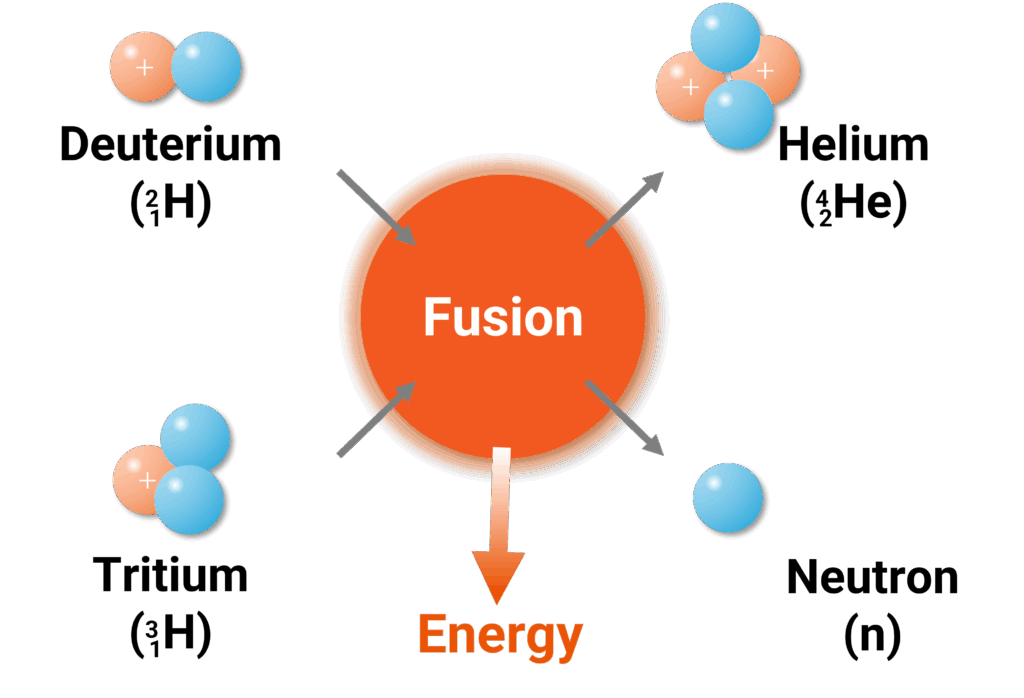

The lithium in the alloy reacts with neutrons produced during fusion to generate tritium, a key fuel for the D-T (deuterium-tritium) fusion reaction.

In other words, LiPb doesn’t just move heat—it helps close the fuel cycle for fusion energy.

Tritium is a critical fuel for fusion, but high-purity tritium is incredibly rare in nature. That means fusion power plants must produce tritium on-site to sustain operations. That’s where LiPb proves its value once again.

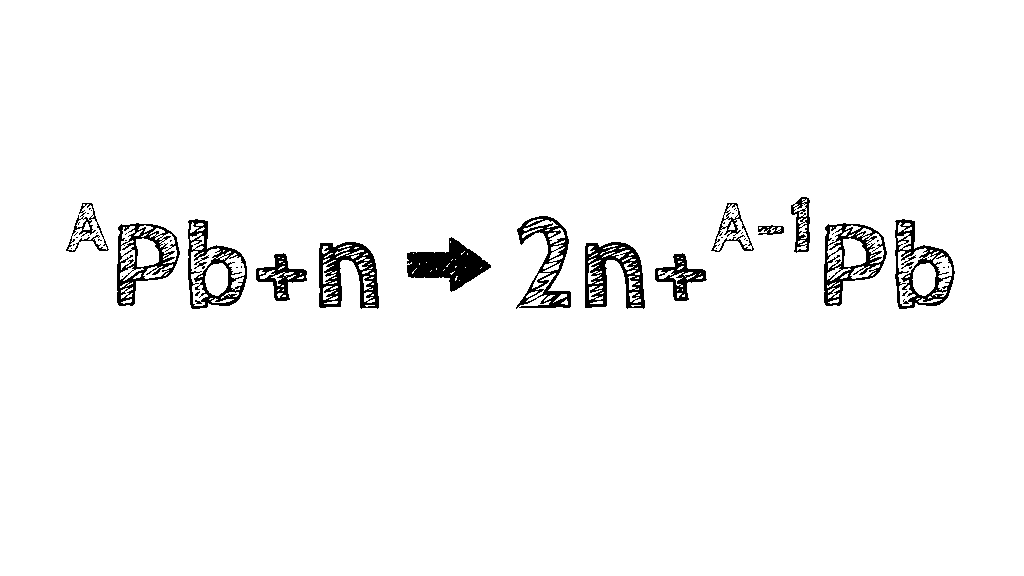

Each fusion reaction produces one neutron, which can then interact with lithium to create one tritium atom. But, to meet the fuel demands of continuous fusion, we need even more neutrons. Enter lead (Pb)—the neutron multiplier.

Heavy elements like lead holding several neutrons can absorb a high-energy neutron and release another in return. This cascade effect helps boost tritium production, making the fusion process more self-sustaining. With LiPb, we’re transporting heat while creating the fuel that powers the future.

This dual capability of efficient heat transfer and fuel generation makes lithium-lead a cornerstone of next-generation fusion energy systems.

Testing Liquid Metal in Development

To unlock the full potential of lithium-lead, we’re running a wide range of tests, starting with how to circulate it safely and efficiently.

At UNITY-1, our piping system is designed to maintain temperatures of up to 1000°C. It’s insulated to minimize heat loss and engineered to account for thermal expansion, ensuring stable operation even under extreme conditions.

We’re also developing hydrogen isotope separation technology using a specialized device called the Vacuum Sieve Tray (VST). In this system, liquid LiPb drips through a series of trays to release tritium from the mixture, which can then be extracted by powerful vacuum pumping systems.

(For safety and regulatory reasons, UNITY-1 uses hydrogen and deuterium in place of tritium during testing.)

Another key area of testing focuses on MHD (magnetohydrodynamic) pressure loss: how strong magnetic fields affect the flow of LiPb.

Because liquid metals conduct electricity, they generate electric currents when exposed to magnetic fields, following Fleming’s Left-Hand Rule. These induced currents can resist the flow of the liquid metal, leading to pressure loss and reduced energy efficiency.

Understanding these MHD effects is essential for efficient heat transfer and for designing the blanket system, which captures high-energy neutrons from fusion reactions and plays a vital role in both energy recovery and tritium production.

At UNITY-1, we’re accelerating development by integrating key devices and systems, bringing together everything from liquid metal loops to heat exchangers to validate our lithium-lead-based power generation technology under fusion-relevant conditions.

As we continue pushing the boundaries of what’s possible in fusion energy, we’ll be sharing more updates through our blog and video series. Stay tuned—and watch the future take shape.

Subscribe to Our Newsletter (LinkedIn)

Follow Us on X, LinkedIn