2025 was a landmark year for Kyoto Fusioneering (KF). We achieved major technical and commercial milestones—advancing plasma heating, blanket technologies, fuel and thermal cycles, and accelerating the FAST project.

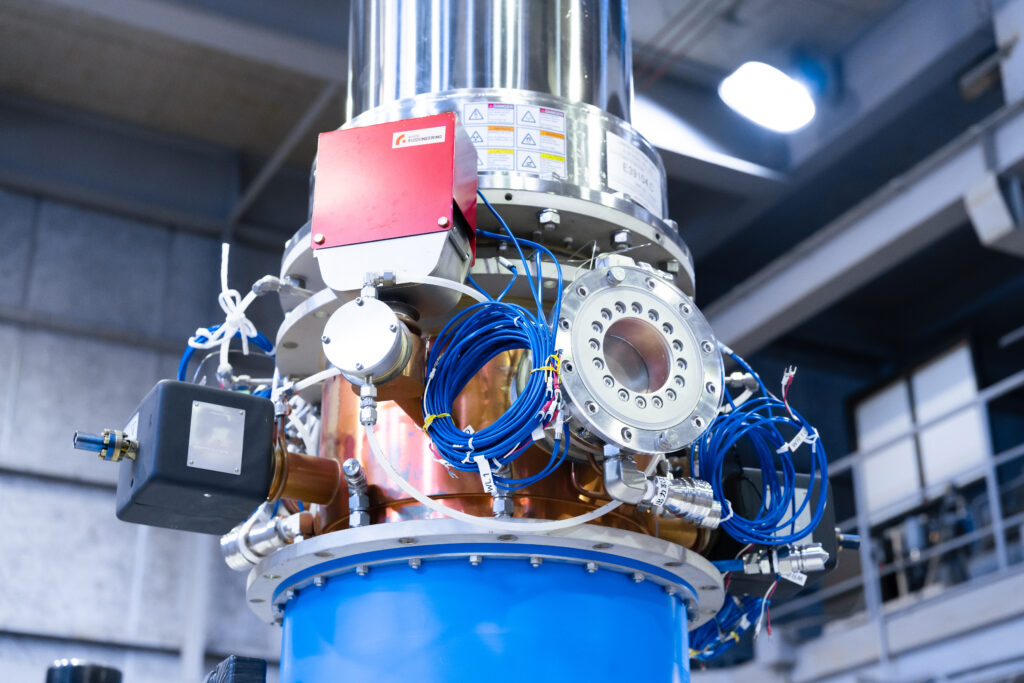

Turning Up the Heat: Gyrotron Milestones

The demand for plasma heating systems (gyrotrons) across public and private programs around the world continues to heat up, and KF’s gyrotron systems remain best-in-class. In 2025, we successfully installed three sets of gyrotron systems, and delivered one:

- Installed one gyrotron system at Tokamak Energy’s high-field spherical tokamak ST40.

- Installed two gyrotron systems (which were delivered in 2024) at UK Atomic Energy Authority’s (UKAEA) spherical tokamak MAST-U.

- Delivered the first of two units to the U.S. Department of Energy’s (DOE) DIII-D National Fusion Facility.

On the development front, we are pushing boundaries to create world-first solutions.

- Higher power gyrotron: Completed the design for a 1.5 to 2 MW class gyrotron for the Wendelstein 7-X stellarator and ASDEX Upgrade at Max Planck Institute for Plasma Physics (IPP).

- Higher frequency gyrotron: Continued development of a 236 GHz class gyrotron, supported by a NEDO (New Energy and Industrial Technology Development Organization) grant.

- R&D and Test Stand: Launched a project to establish a new center in Japan for gyrotron development and testing.

Advancing Blanket Technologies

Surrounding the fusion machine is the breeding blanket, where high-energy neutrons set in motion two critical processes: the capture of thermal energy and the regeneration of tritium for the fuel cycle. Here are the highlights of our blanket technology development in 2025:

- Advanced materials: With silicon carbide fiber composites (SiCf/SiC) and vanadium alloys—advanced materials that can withstand the intense heat of fusion (up to 1000 °C)—we manufactured a variety of complex shapes, which form the building blocks of breeder blanket modules.

- Liquid breeders: Alongside ongoing lithium lead LiPb development (see UNITY-1 below), KF has accelerated work on FLiBe and liquid lithium. FLiBe Research Japan Advanced (FREJA) Loop and Kyoto Liquid Lithium Loop (KL3) are KF’s forced convection loops of candidate liquid breeder materials—enabling technology development and now equipped with industry-grade safety standards.

- In-line tritium sensors: KF spearheaded TRI-PRISM (Tritium Permeation Real-Time In-Line Sensor for Monitoring), a real-time tritium sensor project funded by UKAEA’s LIBRTI (Lithium Breeding Tritium Innovation) program.

- SCYLLA© blanket design: Completed Phase 1 (neutronics, CFD/MHD analysis, tritium transport modeling, and ancillary system scalability assessment) of the SCYLLA (Self-Cooled Yuryo Lithium-Lead Advanced) blanket design for commercial fusion machines, and published our progress in Fusion Engineering and Design.

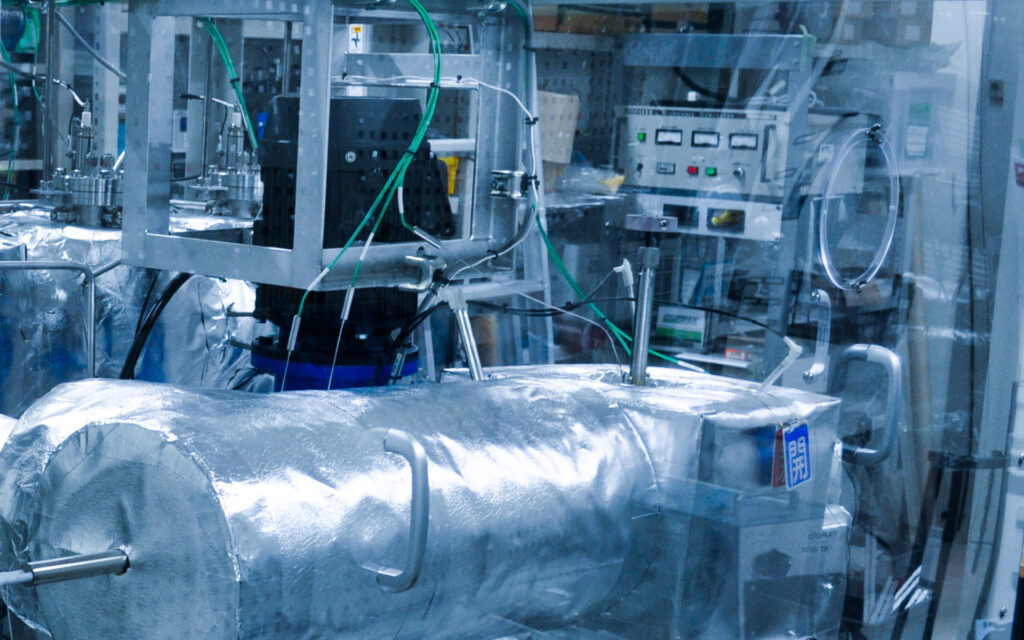

Thermal Cycle: UNITY-1 Powers Up

The thermal cycle, which converts fusion energy into electricity, must operate under the harsh realities of fusion—temperatures soaring to 1000 °C and magnetic fields strong enough to bend liquid metal flows. To tackle these extremes, KF built UNITY-1: our experimental facility to test and refine thermal cycle performance under power plant-relevant conditions. In 2025, UNITY-1 is now operating with:

- Liquid metal: 450 liters of liquid lithium lead (LiPb) has been circulated at 500°C, with a target of 1000 °C in the near future.

- Magnetic field: 4-Tesla magnetic field is operational, enabling studies of magnetohydrodynamic (MHD) effects on liquid metal flow—critical for understanding heat transfer and fluid dynamics under strong magnetic fields.

- Vacuum Sieve Tray (VST): Began testing hydrogen recovery from liquid metal using VST, KF’s proprietary technology. VST disperses tritium-laden liquid metal into small droplets, releasing tritium as gas under vacuum conditions—a key step linking the thermal cycle to the next challenge: the fuel cycle.

The next milestone is in sight: in 2026, UNITY-1 will generate electricity from heat captured in liquid metal—simulating the conversion of fusion-generated thermal energy into usable power.

Fuel Cycle: UNITY-2 Takes Shape and New Partnerships Launched

A robust fuel cycle—extracting, purifying, and recycling tritium—sustains the fusion reaction and is essential for the continuous, economical operation of a fusion power plant, yet achieving it is one of fusion’s greatest technical challenges.

UNITY-2 is the answer to the fuel cycle challenge: the world’s first integrated test facility dedicated to developing the deuterium-tritium fuel cycle. Built in Canada by Fusion Fuel Cycles (FFC), a joint venture between KF and Canadian Nuclear Laboratories, UNITY-2 brings unparalleled tritium-handling and integrated testing to the table. Since publishing our vision for UNITY-2, progress has been accelerating:

- UNITY-2 construction milestone: We officially entered the construction phase of UNITY-2, with crews mobilized to dismantle legacy equipment and clear space for facility upgrades and installation of UNITY-2 process systems.

- New investments: Secured a US$20 million strategic investment from General Atomics to support the UNITY-2 project.

- New simulation tool: Published the Fusion Fuel Cycle Simulator (FFCSim), a new tool that models the entire fusion fuel cycle to help predict performance and inform better design.

UNITY-2 is well on its way to performing critical path derisking of tritium processing technologies and safety systems—cornerstones of the commercial fusion power industry.

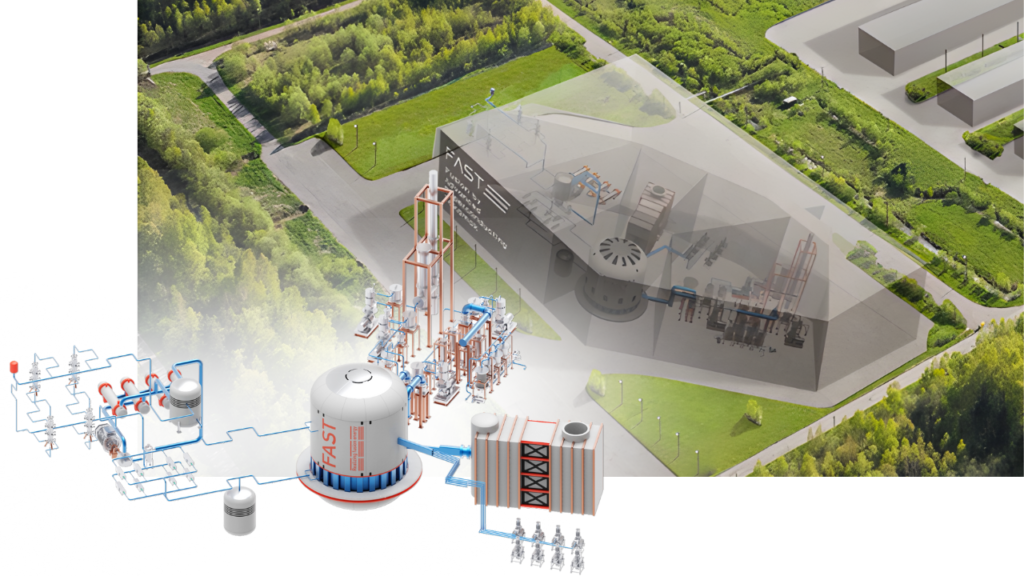

FAST: Accelerating the Path to Fusion Power

KF is a member of the FAST (Fusion by Advanced Superconducting Tokamak) project, where we integrate all strands of our technical development into a singular ambition: to build Japan’s flagship Fusion Pilot Plant (FPP) and demonstrate electricity through fusion. Led by Starlight Engine, FAST will demonstrate integrated fusion power generation using a high-temperature superconducting tokamak. As a cornerstone of Japan’s Fusion Energy Innovation Strategy spearheaded by the Japanese government, FAST tackles critical gaps—breeding blanket systems, high-temperature heat extraction, tritium fuel cycle, and grid-relevant electricity production—toward commercialization of fusion.

Since the launch of FAST in November 2024, Starlight Engine and Kyoto Fusioneering have:

- Completed and published Japan’s first Conceptual Design Report (CDR) for a Fusion Pilot Plant (FPP) and electricity demonstration program.

- Initiated collaborative research with leading universities in Japan including the University of Tokyo, Kyoto University, Kyushu University, Nagoya University, Tohoku University, and Keio University.

- Begun joint R&D with international partners such as General Atomics and Canadian Nuclear Laboratories.

- Started formal discussions with Japan’s Nuclear Regulation Authority (NRA) in preparation for construction.

In 2026, FAST will transition into detailed engineering design.

Looking Ahead

As 2025 closes, KF continues to push the boundaries of fusion innovation. From gyrotrons to FAST project, each step brings us closer to clean, limitless energy.

In 2026, expect these key milestones:

- Advances in gyrotron systems and breeding blanket technologies

- Power generation from UNITY-1

- Site installation and dry-run of UNITY-2

- Expansion of FAST and commencement of engineering design

Stay tuned — the fusion future is unfolding.

Written by Cherry Gao, Ph.D.