Fusion energy systems harness vast amounts of energy which is generated when nuclei collide and fuse. At this time, the fuel atom such as hydrogen must be heated to extremely high temperatures of around 100 million degrees Celsius and become plasma.

One of the devices used for heating plasma is the gyrotron system (hereafter referred to as gyrotron). It plays a crucial role in magnetic confinement fusion reactors.

The gyrotron has been the focus of research and development (R&D) for many years, with contributions from national research institutions and numerous researchers and engineers.

Our company is conducting R&D to produce high-quality Japanese gyrotrons that can stably generate high-frequency and high-power millimetre waves with high efficiency. Additionally, we are working on product management and quality assurance of gyrotrons as a private company.

One of our gyrotrons is currently under performance testing, so I’d like to provide a brief report on the test.

– The Process from Order to Delivery

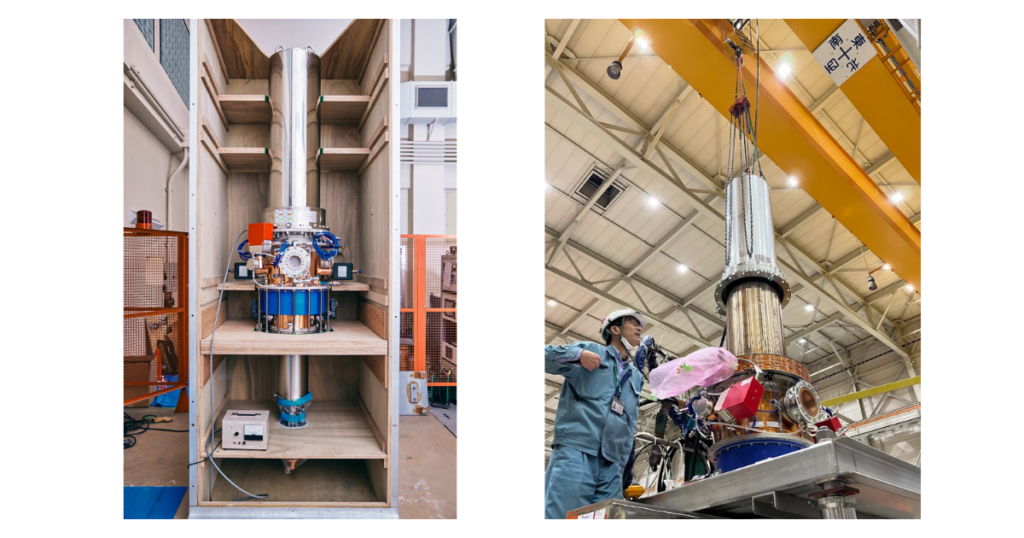

We conduct multiple tests from the order placement to delivery because gyrotrons are extremely precise devices despite their 3 metre length.

The rough process is as follows

“Order” -> “Design” -> “Component Manufacturing (not done by KF)” -> “Assembly” -> “Adjustment and Performance Testing” -> “Transportation” -> “SAT (Site Acceptance Test)” -> “Delivery.”

First, we design a gyrotron based on the specifications requested by the customer and engage professional contractors to manufacture and assemble the components. There are approximately 50 companies contributing their expertise for all the small components involved. In other words, this collaboration is showcasing Japan’s collective technological prowess.

A gyrotron is a device that generates high-power millimetre waves required for heating and controlling of the core plasma. Power supplies and superconducting magnets are essential to generate high-power millimetre waves with a given frequency and power. This integration test is conducted at domestic facilities to confirm its performance. Afterwards, the gyrotron is delivered to the customer’s facility, where a final acceptance test awaits. Only after passing all these tests is the gyrotron delivered.

Whilst it is a very long process, it’s crucial to deliver this device in perfect condition, as it plays an extremely important role in fusion reactors.

Our gyrotron team members face these challenges daily, ensuring that the device meets the highest standards.

– A Brief Report on the Testing Process

We cover the gyrotron located at the National Institute for Fusion Science (NIFS), where we conduct a joint research program.

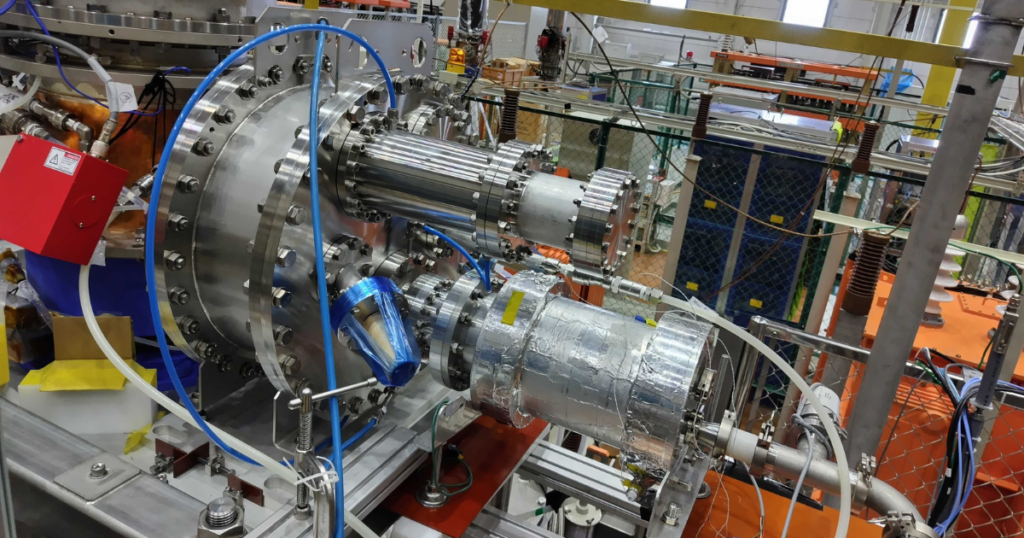

The first step is the installation of the gyrotron for testing. It’s so large that it is carefully mounted on a platform using a crane.

↑The installed gyrotron is equipped with various components attached.

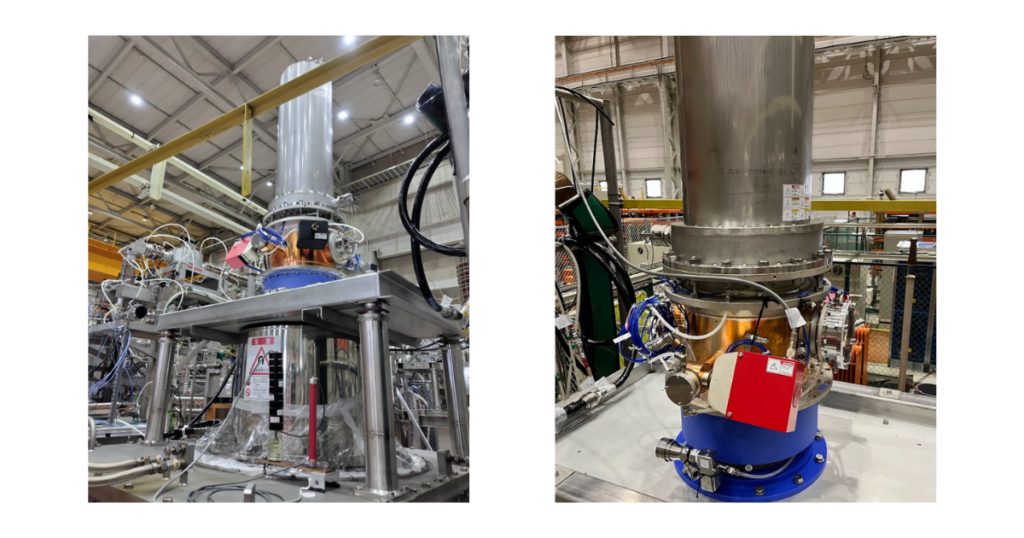

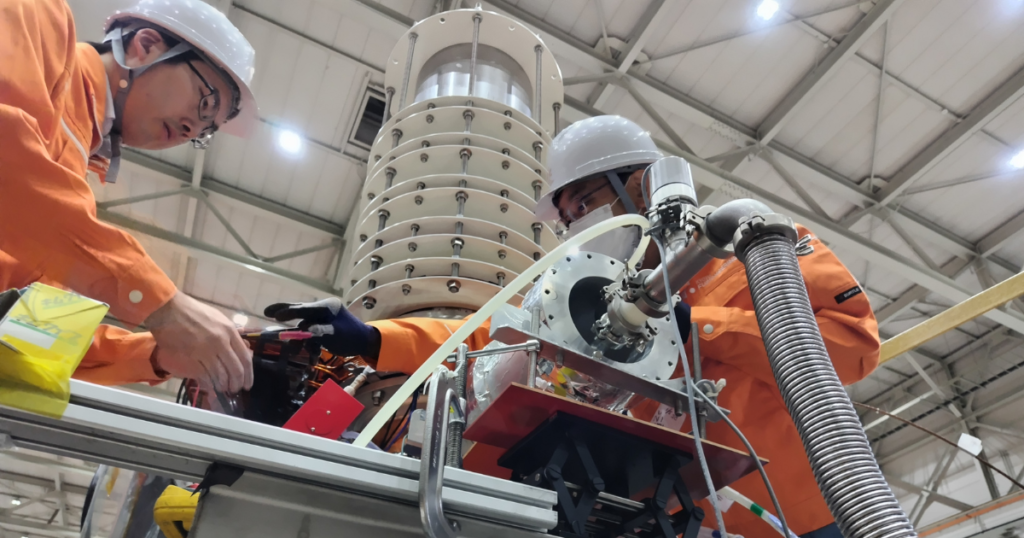

On the day of the photoshoot, we were installing a component called a “dummy load.”

This device absorbs millimetre waves internally and is used to calculate the microwave output from the gyrotron based on the absorbed heat.

Afterward, we conducted various tests, including beam pattern and frequency measurements. These tests are part of the gyrotron tuning and evaluation process.

Then, the gyrotron with a component called a “Matching Optics Unit (MOU)” was installed.

The MOU with multiple mirrors plays a critical role in efficiently delivering millimetre waves generated by the gyrotron to the fusion reactor.

In the future, we will test this gyrotron system, including the MOU before it is shipped to customers overseas.

—

This opportunity allowed us to witness a testing environment that is not typically accessible, emphasising the need for intricate and delicate technology in the equipment required for fusion energy.

While continuing to inherit the high level of technological expertise cultivated by Japanese researchers and engineers, we aspire to contribute to the industrialisation of fusion energy.