In a nutshell:

Kyosuke Namba joined Kyoto Fusioneering (KF) in April 2023 as part of the Thermal Cycle Team within the Plant Technology Division, which oversees R&D of auxiliary equipment for fusion plants. He leads mechanical design for the two UNITY projects.

Leveraging his experience in engineering, procurement, and construction (EPC) from his previous role at a major engineering firm in Japan, Kyosuke continues to take on the challenge of making fusion energy a reality by collaborating closely with international partners.

Could you tell us about your role at Kyoto Fusioneering?

I work as a mechanical engineer for the UNITY-1 and UNITY-2 projects in the Plant Technology Division, where we research and develop auxiliary equipment for fusion plants. My role focuses on basic design, which includes looking at the functions and specifications of the plant, as well as the downstream arrangement and layout of equipment. (For more on our UNITY projects, please see our Technology page.)

What is your role in the UNITY-1 project?

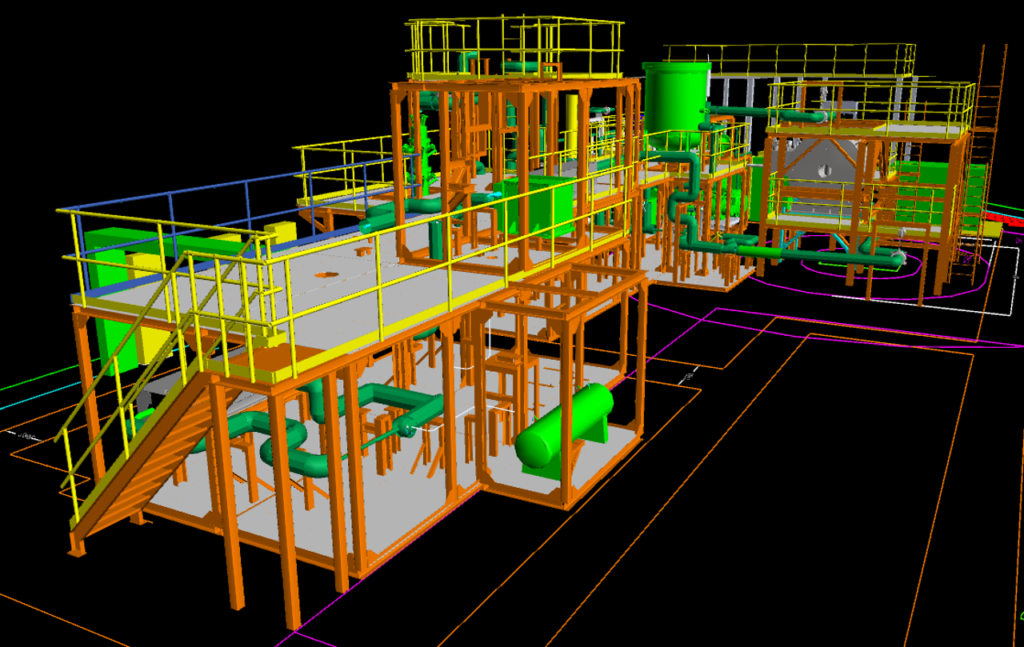

For the UNITY-1 project, I develop the P&IDs (Piping & Instrumentation Flow Diagrams) and equipment and piping layouts. At our construction site for UNITY-1, based in the Kyoto Research Centre (KRC), I’m working on the detailed layout design for the liquid metal loop by collaborating with vendors with future expansion or additional modifications in mind. Thanks to the efforts of all involved, construction is progressing smoothly.

The UNITY-1 project will simulate fusion power generation by operating at temperatures close to the actual liquid metal loop and by demonstrating and developing the key technologies required for even higher temperatures. It is my hope that the knowledge gained from this project will help us develop more reliable systems in the future.

A critical aspect of plant design is evaluating its safety and reliability. To that end, we have conducted a HAZOP (Hazard and Operability Study) with our in-house experts to identify and assess risks during operations, followed by an evaluation of the necessary safety measures. I work closely with team members to ensure the safety of the equipment and make informed design decisions.

Are you also responsible for the mechanical design on the UNITY-2 project?

Yes. UNITY-2 is a joint project with the Canadian Nuclear Laboratories (CNL) that will be built in Ontario, Canada. As we move forward with the conceptual design, we’re collaborating closely with CNL members, since they operate under different regulations from those in Japan. The challenge makes it all the more interesting for me.

I enjoy collaborating with people from different backgrounds. I try to understand the context behind the CNL team’s decisions and base my proposals on that understanding.

Have you worked with international teams before?

Before moving to KF, I had worked primarily in mechanical design at a large engineering firm, where there were many international employees seconded from global affiliate offices.

Also, for EPC (Engineering, Procurement and Construction) projects, I worked in multinational teams since the vendors were often international. While communicating across cultures wasn’t always straightforward, I found it fascinating.

I’ll always remember when I traveled onsite to address a problem or manage design progress at a vendor’s office outside of Japan. Even though I felt some pressure to explain and negotiate on my own, I also realized that I thrived under that pressure. I carry that sense of achievement with me to this day.

Why did you decide to join Kyoto Fusioneering?

I’ve always been interested in the field of fusion energy. One day, I saw an article about KF on my previous company’s bulletin board and started looking into the company. That’s when I realized that Dr Konishi, who was my advisor at university, was one of KF’s co-founders. I deeply respected his broad vision and sharp ideas. Knowing that he was involved gave me confidence that KF was a company I could trust.

In 2022, I began to feel that I wanted to work in an environment where I could broaden my skills as an engineer. This coincided with the timing of my decision to pursue a career change, which led me to apply to KF.

While I was also considering moving internationally, the hiring process at KF progressed quickly, and I joined the company in April 2023.

Were you worried about transitioning from a large company to a startup?

I wasn’t worried at all to be honest. I was already considering international companies, so stability wasn’t my primary motivation for changing jobs. I welcomed the idea of continually taking on new challenges at a startup. Also, during my job search, I heard about KF’s rapid growth in terms of members and funding, which gave me a sense of reassurance.

KF also brings together people who have excelled at major companies and renown research institutions to take on new challenges. I recognized that the skills and expertise I could gain at KF would become valuable assets for my future.

What differences have you noticed between working at a large corporation and a startup?

At KF, our roles cover a wider range of tasks than those at a large company, which might be typical for a startup. At KF, we handle everything from process design to overall layout planning, piping, steel structure design, and individual equipment specifications, all within one division.

In my previous role at a larger firm, the design functions were divided into very specific fields and areas. The design process was highly efficient, and the QA (Quality Assurance) processes were well-refined. Multiple departments were often involved, even for the same tasks. A key feature at KF is that I get to take on a broader scope of work, including tasks I’ve never done before.

The organization is relatively small, so communication is very flat. Sometimes comments or opinions come from unexpected directions and at unexpected times, which can be challenging from an efficiency standpoint. That said, I think many people find it refreshing to work in an environment where you can ask questions right away or share opinions across teams or departments.

What do you prioritize in your work at KF?

I value dedicating myself to the tasks at hand, no matter their size. As we work to make fusion energy a reality for society, I believe there will be significant breakthroughs ahead. I feel a strong sense of responsibility to be part of this mission. While keeping the end goal in mind, I focus on solving each issue step by step, believing that this approach will ultimately lead us to our goal.

I also believe that by repeatedly facing challenges and setbacks, we will reach our goal of making fusion energy a reality, and I will also grow as a professional. Moving forward, I will continue to give it my all and work together with other members to ensure steady progress on our projects.