Our in-house engineering team recently hosted a deep-dive lecture on one of fusion’s most essential tools: the gyrotron—a high-powered microwave generator used to heat plasma in fusion reactors.

In a previous blog post, we shared a behind-the-scenes look at gyrotron testing. This time, we’re going a step further to answer some big questions:

- What exactly is a gyrotron and how does it work?

- How has Japan led the way in gyrotron development and how is KF bringing this technology to the world?

As part of our Fusion 101 series, this post is designed to keep things clear, interesting and accessible. We’ll take a closer look at the science behind the gyrotron—and how it’s shaping the future of clean energy.

What do gyrotrons and microwaves have in common? More than you think…

Microwave ovens heat food using electromagnetic waves—a principle that also applies to gyrotrons. These devices generate microwaves to heat materials, much like their household counterparts.

The key difference lies in power: a gyrotron can provide 1,000 to 2,000 times more power than a typical microwave oven, reaching outputs of up to 1 megawatt (MW).

Why is so much power needed for fusion?

Fusion reactions require temperatures of over 100 million degrees Celsius, hotter than the sun’s core. Reaching these extreme conditions means heating and confining plasma with intense precision and energy.

That’s where the gyrotron comes in. It efficiently converts electrical power into high-frequency microwaves, delivering the energy needed to heat plasma to fusion-ready temperatures.

Why use a gyrotron for plasma heating?

In magnetic confinement fusion systems—like tokamaks and helical devices—gyrotron-based microwave heating plays a crucial role. (For more on confinement methods, check out another post in our “Fusion 101” series!)

To heat plasma confined by magnetic fields, extremely high-frequency, high-power electromagnetic waves are required. That’s exactly what a gyrotron delivers—making it an essential component in achieving the temperatures needed for fusion.

Why have gyrotrons been chosen over other approaches?

Simply put, they bring power, precision and flexibility.

Since microwaves can be efficiently transmitted over long distances using a device called a waveguide, the gyrotron can be installed farther away from the reactor. This allows for more flexible system design and improves safety around the fusion core.

Also, the direction of the microwave beam can be finely tuned using mirrors. This allows engineers to target specific, cooler areas of the plasma, making heating more efficient and effective.

How do gyrotrons work?

Let’s break it down into five simple steps!

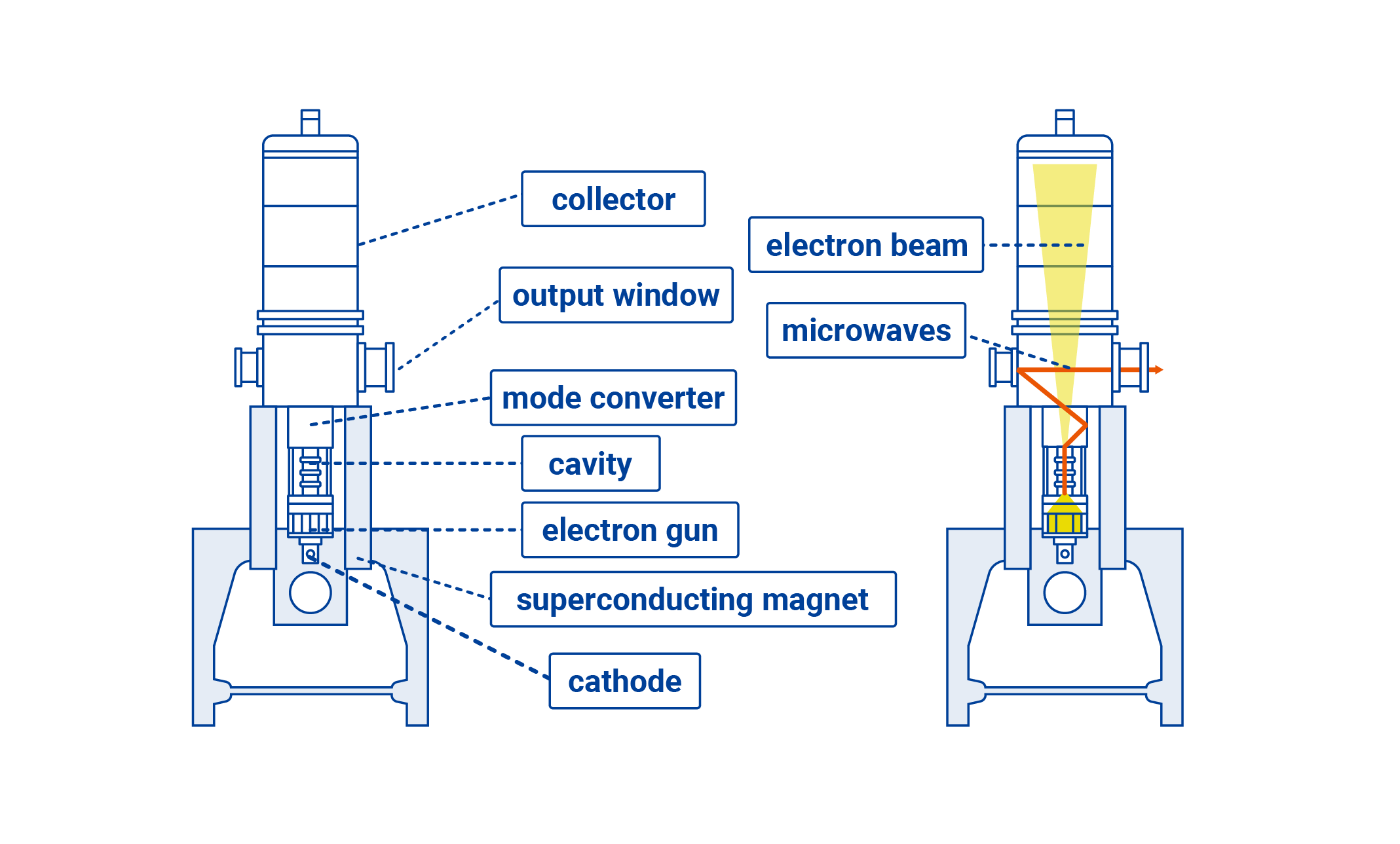

1. Generating the electron beam

It all starts with a heated cathode at the base of the gyrotron. When high voltage is applied, it emits electrons, forming an electron beam (shown in yellow).

2. Creating microwaves

The electron beam spirals upward through a powerful magnetic field generated by a superconducting magnet (SCM). This spiraling motion—known as cyclotron motion—continues inside a metallic resonant cavity, where the electrons interact with the electromagnetic field. As they spiral, they release energy in the form of microwaves (shown in red).

3. Shaping the microwaves

At first, the microwaves have a complex shape. A mode converter reshapes them in a form that minimizes energy loss during transmission and reduces thermal stress on components like the output window.

4. Outputting the microwaves

Next, the shaped microwaves are reflected and directed by internal mirrors, then emitted through the output window, which is made of artificial diamonds. This high-performance material offers:

- Excellent microwave transparency

- Superior thermal conductivity

- High heat and wear resistance

- Electrical insulation to prevent discharge

5. Absorbing the electron beam

After releasing their energy, the electrons are absorbed by a collector at the top of the gyrotron. This helps stabilize the current and ensures safe operation.

From Device to System: The Gyrotron as a Complete Solution

While this post has focused on the gyrotron itself, operating it in a real-world fusion plant requires much more. A gyrotron must be integrated with a range of supporting components to function effectively as a part of a complete, operational solution.

Japan has played a leading role in gyrotron development for decades, led by institutions like QST (National Institutes for Quantum Science and Technology). In 2021, QST successfully delivered eight gyrotrons for the international ITER project.

Building on that legacy, we’re advancing gyrotron technology with higher frequencies and longer pulse durations, pushing toward solutions that are ready for global deployment and industrial applications.

We’re also driving the productization of gyrotrons—bringing a private-sector approach to quality assurance and system integration. Rather than simply delivering the device, we provide complete gyrotron systems tailored to each customer’s needs. These systems include:

- High-voltage DC power supply to operate the gyrotron

- Superconducting magnets that generate a powerful magnetic field

- Precision support structures to hold and align the entire system

- Cooling manifolds to prevent overheating

- Oil tanks for electrical insulation and discharge suppression

- Instrumentation panels for real-time control and monitoring

This approach ensures that each gyrotron is not just a standalone device, but a fully integrated, reliable solution—ready for deployment in advanced fusion and industrial environments.

As a fabless company, we work closely with over 50 Japanese manufacturing partners to build a strong and reliable supply chain. Each component is carefully assembled and tested at our R&D facilities, ensuring quality and performance before being shipped to customers.

Once delivered, our engineers then travel on-site to support installation, training, and final testing through Site Acceptance Tests (SAT)–making sure every system is fully operation and ready to go.

We hope this Fusion 101 blog post has helped to shed light on how the gyrotron system works and why it’s so important to fusion energy.

Stay tuned for more insights into our technology and get to know the people behind it in our upcoming “Behind the Fusion Scene” interview series!

Subscribe to Our Newsletter (LinkedIn)