In a nutshell:

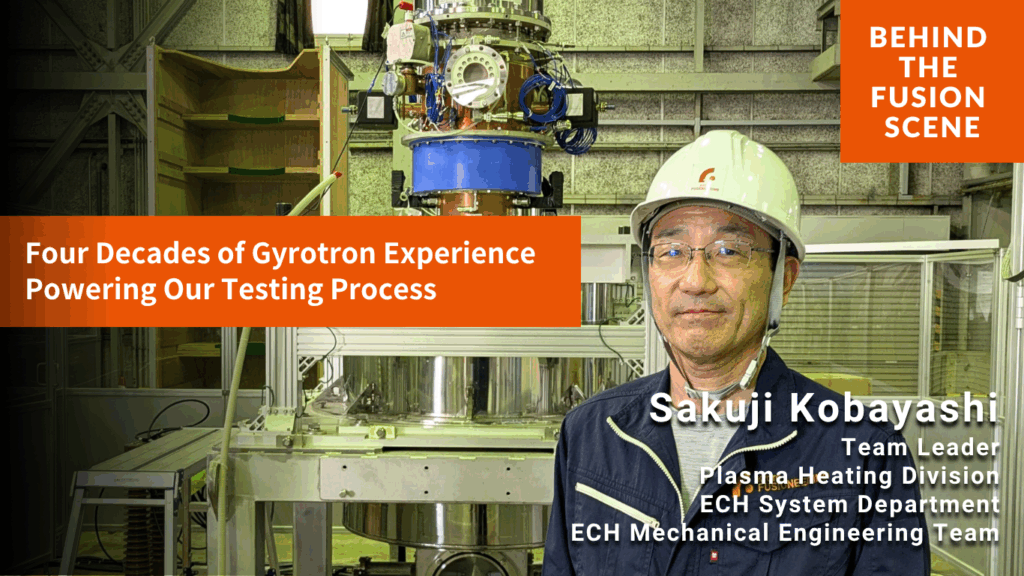

Sakuji Kobayashi joined Kyoto Fusioneering (KF) in April 2023. As the leader of the ECH Mechanical Engineering Team, he oversees the installation and performance testing of gyrotron systems, key components in plasma heating. With over 40 years of experience at institutions like Kyoto University and the National Institute for Fusion Science (NIFS), he brings in-depth technical knowledge to the team and is also committed to passing on his expertise by mentoring younger engineers.

How did you first learn about fusion energy?

It all started around the time I graduated from high school. I had passed the national civil service exam and planned to work in MEXT (Ministry of Education, Culture, Sports, Science and Technology) while taking evening classes at a university in Kyoto.

Around that time, I was contacted by the National Personnel Authority, who shared with me that Kyoto University was hiring technical staff to help launch a new plasma device called Heliotron E.

At the time, I didn’t know much about fusion energy, but the phrase “cutting-edge development of future energy” in the job description really caught my attention. That sense of curiosity, and my lifelong love of making things, pushed me to take the job while continuing my studies.

Looking back, I never imagined that this first step would lead to a career in fusion energy that’s lasted over 40 years.

What kind of experiences did you have as part of the technical staff?

At Kyoto University’s Heliotron E, a medium-sized plasma device, I oversaw equipment management and operations. This included installing and running externally procured plasma heating systems known as gyrotrons. I also played a key role in launching a smaller experimental device, Heliotron DR, where I handled tasks like wiring, setting up exhaust systems, and installing measurement instruments.

When I joined the Heliotron E project, it was already in the final stages of design and construction. For Heliotron DR, I was able to participate from the design phase. That gave me a much deeper level of involvement and hands-on experience throughout the project.

Since I majored in mechanical engineering at university, I had some background knowledge of equipment operation and maintenance, but fusion energy was a completely new world for me. I learned a lot by reading books and technical materials, and, more importantly, by observing and working closely with other team members.

At that time, Japan was still in the early stages of developing its own gyrotrons. So, having the opportunity to work with gyrotrons from the US and Russia was incredibly valuable and rare. It gave me insight into different technologies and approaches at an early stage in my career.

What kind of work did you do at the National Institute for Fusion Science (NIFS)?

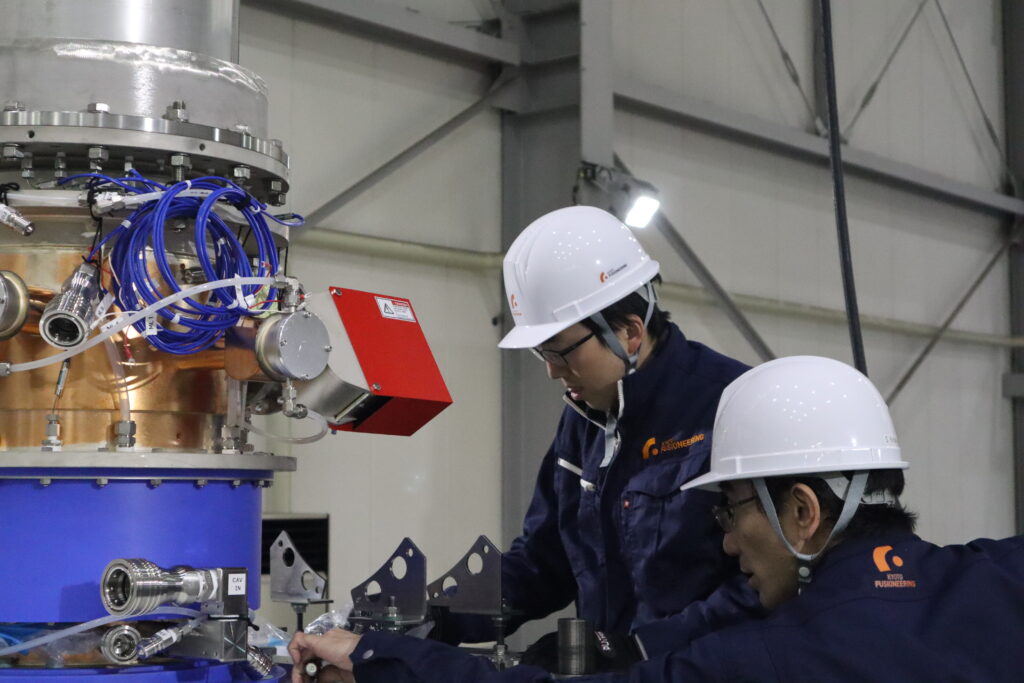

Later in my career, I was transferred to the Electron Cyclotron Resonance Heating (ECH) group at NIFS (National Institute for Fusion Science). Around that time, experiments with the Large Helical Device (LHD) were just beginning. I was responsible for the introduction and operation of several of the roughly 20 gyrotrons used in the system. My work involved fine-tuning and controlling each unit to ensure it produced microwaves exactly as designed.

The LHD is a large and complex device, and all of its systems, including gyrotron tubes, power supplies, support structures, and cooling systems, are closely interconnected. Sometimes, unexpected results would occur, and tracking down the cause could take a lot of time and effort.

Working within a limited budget, we ran repeated tests, collected data, and collaborated closely with suppliers to complete performance testing of the gyrotron systems. My earlier experience at Kyoto University with small and medium-sized devices proved to be very helpful—it allowed me to communicate smoothly with other team members and apply what I had learned to this much larger and more complex setup.

When the tests succeeded, I felt a strong sense of accomplishment. It was a rewarding moment that reminded me how far I had come since first entering the fusion field.

Why did you decide to start a new chapter at KF after such a distinguished career in the public sector?

After reaching retirement age, I continued working part-time at NIFS. Once the LHD testing had settled down, I started thinking about what I wanted to do next.

Around that time, I got a call from Dr. Sakamoto, KF’s CTO, who I had previously worked with on a gyrotron project, inviting me to join KF.

To be honest, I was a bit hesitant at first. I wondered if working at a fast-moving startup might be too much for me. But I also saw it as a chance to try something new. I later found out that Dr. Tsujimura, who had also been my colleague at NIFS, was planning to join as well. That gave me a sense of reassurance and encouraged me to take the leap.

What are your responsibilities at KF as part of the gyrotron team?

I lead the ECH Mechanical Engineering team, where I apply my experience to assemble, install, and operate gyrotron systems—complex setups that combine the gyrotron tube with a range of peripheral components. I’m also involved in designing the surrounding equipment that supports these systems. (If you’re curious to learn more about how gyrotrons work, check out our earlier blog post!)

In addition to hands-on technical work, I oversee on-site operations to ensure everything runs safely and efficiently. My goal is to create an environment where each team member can do their best work. Some of our engineers started working with gyrotrons only after joining KF, so I try to share key procedures and practical tips based on my years of experience.

While most of our testing and adjustment work takes place at sites in Japan, I recently had the opportunity to visit Tokamak Energy (TE), a fusion startup in the UK. I supported the installation of one of our gyrotron systems and confirmed the procedures for the Site Acceptance Test (SAT).

When the system was installed, the TE engineers broke into applause—it was clear they had been looking forward to this moment. I felt proud and relieved to see our system delivered and up and running. Later, when TE shared the milestone on social media, it gave me a renewed sense of satisfaction and accomplishment.

From your perspective, having worked with gyrotrons for over 40 years, how has the technology evolved?

The technology has come a long way since I first started.

For example, the superconducting magnets used to generate the strong magnetic fields required for microwave oscillation have seen major improvements. In the past, we had to inject liquid nitrogen or helium daily—even on weekends—to keep the magnets cold. Today, electrically cooled systems have replaced cryogenic coolant, making operations much more efficient and manageable.

There have also been advances in how microwaves are emitted. Modern gyrotrons emit microwaves sideways through output windows made of synthetic diamond, allowing for higher-frequency oscillation. This development was led by Dr. Sakamoto during his time at the National Institutes for Quantum Science and Technology (QST).

As a side note, this output window project was actually how I first met Dr. Sakamoto. At the time, I was working with his team on developing a mode converter to enable sideways microwave emission. That collaboration ended up being a meaningful one because it eventually led to my joining KF.

Finally, what do you hope to achieve at KF?

My goal is to carefully carry out each adjustment and performance test, and to deliver gyrotron systems that meet—and exceed—our customers’ expectations. By building a strong track record of reliability and results, I believe we can earn even greater trust in our technology, which will lead to more orders and continued business growth.

Looking ahead, our team will keep pushing to refine and improve our systems. I hope that KF’s gyrotron technology will play a key role in making fusion energy a reality.